When you've got employees standing on hard, unforgiving floors all day, you're dealing with more than just sore feet. It's a direct hit to your business's productivity and your team's overall well-being. That’s where industrial anti-fatigue mats come in. They aren't just floor coverings; they're a crucial ergonomic tool that provides a cushioned, supportive surface, actively fighting the effects of standing for long hours. The result is a workforce that's safer, more focused, and ultimately, more efficient.

The Real Cost of Standing Still in the Workplace

Picture a dedicated worker on a busy production line. At the start of their shift, they’re sharp and their output is high. But as the hours wear on, that unforgiving concrete floor starts to take its toll. What began as a subtle discomfort in their lower back is now a nagging ache. Their feet are throbbing. Their focus starts to drift. This isn't just a personal problem—it's a real, tangible business issue with costs you can measure.

The human body simply wasn't built to stand still on hard surfaces for eight-hour shifts. This static posture restricts blood flow in the legs and forces muscles into overdrive just to keep the body upright. The outcome is a chain reaction of negative effects that directly hit your bottom line.

The True Cost of Worker Fatigue vs. The Solution

It’s easy to overlook the slow drain of worker fatigue until you see the numbers. The issues it causes are often seen as separate problems, but they all stem from the same root cause: physical strain. Here’s a direct comparison of the problem versus the solution.

| Problem (Without Mats) | Impact on Business | Solution (With Industrial Anti-Fatigue Mats) |

|---|---|---|

| Physical & Mental Fatigue | Productivity drops, focus wanes, and output decreases over a shift. | Sustained Productivity: Workers stay comfortable and focused, maintaining consistent output all day. |

| Lack of Concentration | Error rates climb, leading to wasted materials, rework, and quality issues. | Improved Accuracy: Reduced physical distraction leads to fewer mistakes and higher quality work. |

| Chronic Pain & MSDs | Absenteeism increases as employees deal with back, leg, and joint pain. | Lower Absenteeism: Proactive ergonomic support reduces pain-related absences and promotes well-being. |

| Long-Term Health Issues | Risk of chronic conditions like varicose veins and joint damage rises. | Enhanced Worker Safety: Reduces strain, lowers the risk of long-term injuries, and fosters a safer work environment. |

Ignoring the physical toll on your team isn't just a comfort issue; it's a strategic misstep that chips away at your operational efficiency day after day.

The Smart Ergonomic Solution

This is exactly where industrial anti-fatigue mats step in as a powerful, strategic solution. These mats are far more than just a bit of padding. They are engineered ergonomic tools designed to encourage subtle, continuous micro-movements in the leg and calf muscles while a person stands.

These tiny, almost unnoticeable movements are the key. They get the blood flowing again, preventing it from pooling in the legs and making sure oxygen is delivered efficiently throughout the body. It’s a simple action with a profound impact.

This isn’t a secret, either. The growing awareness of ergonomic safety is clear in market trends. The global anti-fatigue mats market is on track to grow from around USD 1.80 billion to a projected USD 3.09 billion by 2034. This major increase shows a real shift in how businesses are starting to see employee well-being as a cornerstone of operational success.

By adding a well-designed mat, you completely change the dynamic between your employee and their workspace. The strain on their back, legs, and joints is dramatically reduced. To dig deeper into the mechanics, you can learn more about what anti-fatigue mats are and the science that makes them work. The end game is a more comfortable, alert, and consistently productive team member who can maintain their peak performance all shift long.

How to Choose the Right Mat Material for Your Floor

Picking the right material is hands-down the most important decision you'll make when buying industrial anti-fatigue mats. Get it right, and you’ve got a long-lasting, safe, and comfortable surface. Get it wrong, and you’re looking at premature wear, potential safety issues, and a wasted budget.

Think of it like choosing tires for a truck. You wouldn't put standard street tires on a rig that's headed for a muddy, debris-filled construction site. In the same way, your mat’s material has to be perfectly matched to the real-world demands of your floor. Let's walk through the options so you can make a smart, practical choice.

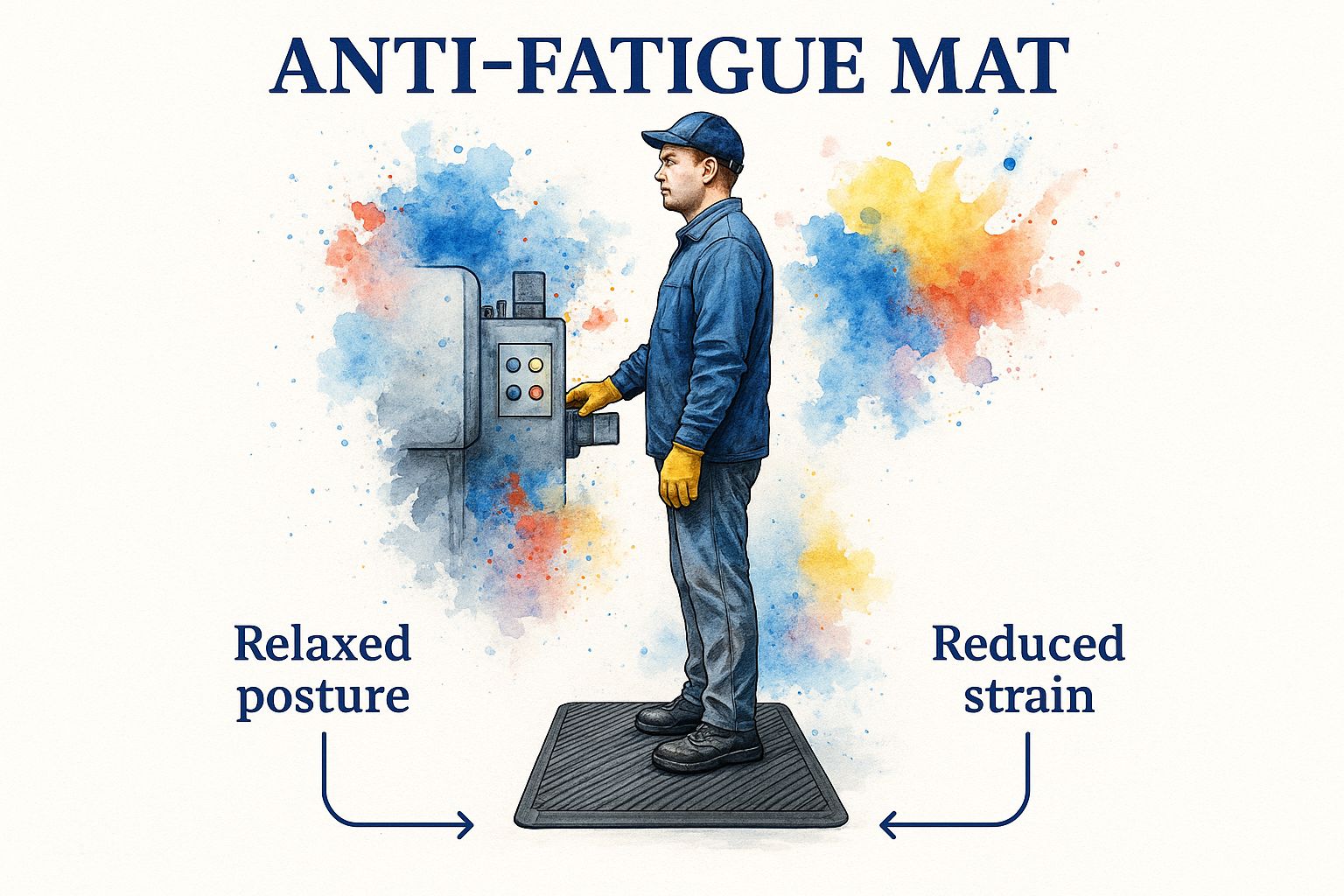

This image shows just how much a proper mat can do for a worker's posture and overall physical strain.

As you can see, the mat provides crucial support, encouraging a more natural stance. This small change is the key to preventing long-term muscle and joint problems. To really understand the science behind this, check out our guide on how anti-fatigue mats directly impact your health.

Start by Understanding Your Environment

Before you even look at materials, you need to take a hard look at your workspace. The first step to choosing the right mat is a quick but thorough assessment of the area. This ensures you invest in a solution that solves your problems instead of creating new ones.

Actionable Takeaway: Your 3-Point Environment Check

- Identify Liquids: What's on the floor? Is it just water, or are you dealing with oils, grease, and harsh chemicals? The answer dictates the chemical resistance you need.

- Assess Traffic: How much foot traffic is there? Is it for a single-person workstation, or a busy assembly line where carts and trolleys roll through? This determines the durability required.

- Analyze Work Type: What kind of work happens here? Does the job create sparks from welding, or is it a dry, static-sensitive area for electronics? This will point you toward specialty mats.

Answering these questions first will instantly point you in the right direction and make the selection process much simpler.

A Practical Comparison of Mat Materials

While there's a whole world of materials out there, most industrial jobs come down to three main contenders: Rubber, Vinyl, and Polyurethane. Each one has its own unique strengths and is best suited for different situations.

Industrial Mat Material Performance Guide

To make things even clearer, here’s a quick comparison of how these materials stack up against each other in different industrial settings. Use this table as a starting point to narrow down the best fit for your specific needs.

| Material | Best For (Environment) | Durability Rating | Chemical Resistance | Comfort Level |

|---|---|---|---|---|

| Rubber | Oily, greasy, heavy-duty areas, welding zones | Excellent | High (especially Nitrile) | Good |

| Vinyl (PVC) | Dry, general-purpose, light to medium traffic | Good | Moderate | Good |

| Polyurethane | Dry, clean rooms, labs, assembly lines | Excellent | Low | Excellent |

Ultimately, the best choice is the one that aligns perfectly with your facility's daily challenges. Rubber is your heavy-hitter, Vinyl is the all-rounder, and Polyurethane is the specialist for pure comfort in dry areas.

Rubber: The Heavy-Duty Workhorse

When you need a mat that can take a beating, rubber is your go-to. It's the undisputed champion for tough, demanding industrial environments.

Rubber offers incredible durability and resilience, easily standing up to heavy foot traffic, dropped tools, and even rolling carts without breaking a sweat. It’s no surprise that it’s the most common material for industrial mats.

- Real-World Example: Picture a busy CNC machine shop. The floor is constantly slick with cutting fluids and covered in sharp metal shavings. In this scenario, a nitrile rubber mat isn't just a good choice—it's the only safe choice. Its natural resistance to oils and grease keeps it from becoming a slippery mess, while the tough surface simply shrugs off the harsh debris. The direct benefit is a dramatic reduction in slips and falls, a key safety metric for any shop.

Vinyl: The Versatile and Cost-Effective Option

Vinyl mats are a hugely popular and versatile choice, hitting that sweet spot between comfort, performance, and price.

They are typically lighter than rubber and offer solid resistance to most common chemicals and water. This makes them a great fit for a wide range of general-purpose applications where you need good ergonomic support without the extreme durability of rubber.

- Real-World Example: Think of a parts-kitting and packaging station in a warehouse. The environment is relatively clean and dry, but workers are on their feet all day. A PVC vinyl foam mat is perfect here. It provides fantastic cushioning to fight off leg and back pain at a budget-friendly price. The benefit to the business is improved worker morale and sustained productivity throughout the shift, as comfort directly impacts focus.

Polyurethane: The Premium Comfort Provider

When your number one priority is maximum ergonomic comfort, nothing beats polyurethane.

These mats offer a softer, more cushioned feel that delivers exceptional support throughout a long shift. While they are usually a more premium investment, the superior cushioning and impressive durability in dry environments often mean they outlast other options, providing excellent long-term value.

- Real-World Example: Consider an electronics assembly line where technicians have to stand with intense focus for hours at a time. The area is clean, dry, and static-controlled. A polyurethane mat is the ideal solution. Its top-tier cushioning actively fights discomfort. The direct benefit is that it helps technicians stay focused and precise—which is absolutely critical for preventing costly errors when working with tiny, sensitive components.

Finding Specialty Mats for Demanding Environments

Not all industrial settings are built the same. While a standard industrial anti-fatigue mat is a game-changer in a dry assembly area, some workspaces throw much tougher challenges at you. In those places, a generic mat isn't just a poor choice—it can be a serious safety hazard and a costly mistake.

When you're dealing with extreme conditions, you need a mat that's been specifically engineered for the job. These aren't just about comfort; they have built-in properties to protect your products, your equipment, and most importantly, your people. They're an absolute must for keeping your most critical work zones safe, compliant, and running smoothly.

ESD Mats for Electronics Assembly

In any facility that handles electronics, static electricity is the silent saboteur. One tiny, unnoticed zap from a worker can instantly fry a delicate circuit board or microchip. That means failed products, angry customers, and expensive rework. This is exactly why Electrostatic Dissipative (ESD) anti-fatigue mats are non-negotiable.

These mats are designed to do one thing brilliantly: safely pull static electricity away from a worker and send it to the ground before it can cause damage. They give you all the ergonomic benefits of an anti-fatigue mat while serving as a crucial line of defense for your valuable components.

- Real-World Example: Imagine an aerospace company that builds sensitive navigation systems. A technician walking across a normal floor could build up enough static to destroy a million-dollar component with a single touch. By placing ESD anti-fatigue mats at every workstation, the company creates a static-safe zone. The mats continuously dissipate any charge, keeping every single component protected from electrostatic discharge, thereby safeguarding the entire production process.

Welding Mats for Hot Work Areas

Welding and fabrication shops are among the most brutal environments for any kind of flooring. Hot sparks, molten slag, and metal droppings can melt or even ignite standard vinyl or rubber mats in an instant. This creates a massive fire hazard and turns your investment into a melted mess.

That's where welding-safe mats come in. They are built to take a beating, typically made from a high-density, specially formulated rubber that is self-extinguishing and shrugs off extreme heat. This means they won't catch fire and will keep providing ergonomic support, even in the most punishing conditions.

- Actionable Takeaway: When you're buying a mat for a welding bay, always check that it has a "welding-safe" certification. A regular "heavy-duty" mat just won't cut it. The real benefit here is fire prevention and durability against hot sparks, which protects both your crew and your facility.

Antimicrobial and Drainage Mats

In places like food processing plants, healthcare facilities, and cleanrooms, hygiene is everything. A standard mat can quickly become a breeding ground for bacteria, mold, and other germs, posing a serious contamination risk. Antimicrobial mats solve this by being infused with agents that stop microorganisms from growing on the surface.

If those areas are also wet, a drainage mat becomes essential. These mats have holes and raised surfaces that let liquids flow right through, keeping the top surface dry and slip-resistant. Many of the best options combine both features, offering an antimicrobial drainage mat for a complete solution.

As material science advances, even more specialized mats are hitting the market. For instance, the demand for gel anti-fatigue mats is projected to grow by an 8% CAGR, signaling a shift toward more advanced cushioning in specialized fields. You can dive deeper into this trend in this market research on anti-fatigue mats.

- Real-World Example: Think about the dishwashing area in a busy commercial kitchen. Water, grease, and food scraps are constantly hitting the floor. A solid mat would just trap all that gunk, creating a slick, disgusting hazard. An antimicrobial drainage mat, however, lets the water flow away, provides a stable, non-slip footing, and fights off bacteria, keeping the area safe and sanitary. This directly contributes to passing health inspections and preventing slip-related injuries.

Getting Sizing and Placement Right the First Time

You’ve decided to invest in quality industrial anti fatigue mats — that’s a great first step. But the job is only half done. If a mat is too small or shoved in the wrong spot, you’re not just losing the ergonomic benefits; you could be creating brand-new safety hazards. A mat that’s too small forces workers to constantly step on and off the edge, which is a massive distraction and a trip risk.

The most common mistake is buying a small mat that only fits where a person stands still. But industrial work isn't static. People pivot, reach for parts, and shift their weight. Getting the size right isn't about covering a patch of floor; it's about covering the workflow.

How to Measure for How People Actually Work

To avoid this common blunder, you need to measure for a worker's entire range of motion during their tasks. This ensures continuous support, no matter where they move within their workstation.

Here's a simple, step-by-step process to get it right:

- Observe the Task: Watch an employee perform their job. Pay close attention to every step, pivot, and reach.

- Mark the Boundaries: Use temporary tape to mark the outer limits of their movement on the floor. Where do they stand? Where do they step to grab parts or tools?

- Measure the Footprint: Measure the maximum width and depth of the taped-off zone.

- Add a Safety Buffer: Add at least 15cm (6 inches) to both the width and depth. This buffer ensures they remain safely on the mat even with unexpected movements.

Following these four steps will give you the exact dimensions you need, empowering you to order the perfect size.

Real-World Example: A Machine Operator’s Workspace

Picture a machine operator running a large piece of equipment. Their workflow involves a few key movements:

- They stand at the central control panel to monitor the machine.

- They pivot left to grab raw materials from a bin.

- They step right to place finished parts onto a conveyor.

If you just bought a small 2'x3' mat and placed it at the control panel, they'd be stepping off it dozens of times an hour, defeating the purpose and creating a trip hazard. By mapping their workflow, you’d see they need a much larger mat—perhaps a 4'x8' one—that covers the entire arc of movement. The benefit is seamless support and the elimination of a dangerous trip point.

The Critical Role of Beveled Edges

Once you've nailed the size, proper placement and design are the final pieces of the puzzle. The single most important design feature for safety is beveled edges.

These sloped or tapered edges are a non-negotiable safety feature. They create a smooth ramp from the floor to the mat's surface, which accomplishes two vital things:

- Prevents Trips: The ramp-like edge dramatically cuts down the risk of someone catching their foot.

- Allows Cart Traffic: It lets pushcarts and trolleys roll over the mat smoothly without snagging.

A mat without beveled edges is an obstacle waiting to cause an accident. Always ensure any industrial anti fatigue mats you consider have them on all exposed sides.

Installation and Maintenance to Maximize Mat Lifespan

You’ve made a smart investment in your team’s well-being by purchasing high-quality industrial anti fatigue mats. But just like any tool, its value depends on how you care for it. Proper installation and maintenance are essential for protecting that investment and ensuring your mats deliver results for their entire service life.

A mat that isn't installed correctly can slip, and one that isn't maintained can curl up, creating a trip hazard.

Flawless Installation Starts with the Floor

Before unrolling a new mat, ensure the floor underneath is clean, dry, and level. This is non-negotiable for a safe setup.

Start by giving the area a thorough sweep and mop to remove all dust, debris, and any grease or oil. A dirty floor will let the mat shift, while trapped moisture can lead to mould.

- Real-World Example: Imagine a new mat being placed on a floor in a commercial kitchen that wasn't properly degreased. Day after day, the trapped oils not only make the mat slip but also start to eat away at its rubber backing. This simple mistake slashes the mat's lifespan and creates a serious, ongoing slip risk for the staff.

Creating a Practical Cleaning Schedule

Once your mat is down, a regular cleaning routine is your number one defense against premature wear. The method depends on the mat’s material and the daily mess.

Actionable Cleaning Tips:

- For Vinyl (PVC) Mats: Stick with a neutral pH cleaner. Harsh chemicals make vinyl brittle and lead to cracking. A simple mop with mild soap is usually enough.

- For Nitrile Rubber Mats: If you're dealing with grease and oil, use a strong degreaser to break down the residue and maintain a slip-resistant surface.

- Daily Care: At the end of every shift, sweep or wipe down mats to clear off surface debris. This simple step prevents dirt from being ground into the mat, preserving its cushioning.

The Proactive Inspection Checklist

Don't wait for an accident to tell you a mat is finished. A quick weekly inspection can help you catch wear and tear before they become real problems. This check only takes a few minutes but can prevent injuries and early replacement costs.

Here’s a simple checklist to follow:

- Check the Edges: Are the beveled edges curling up or tearing? Curled edges are a primary trip hazard.

- Inspect the Surface: Do you see cracks, rips, or holes? These trap dirt and signal that the mat's structure is failing.

- Feel for "Dead Spots": Press down on different parts of the mat. Does it still feel cushioned, or are there areas that feel flat and compressed ("bottoming out")? If so, those spots offer no ergonomic benefit.

- Confirm Placement: Has the mat shifted? Ensure it’s still covering the entire workflow area.

- Actionable Takeaway: A mat with curled edges or "dead spots" has stopped being an anti-fatigue solution and has become a trip hazard. Once you see these signs, it must be replaced to keep your workplace safe.

Knowing when to replace a mat is just as crucial as knowing how to maintain it. For a deeper dive, you can learn more about how long anti-fatigue mats last and what influences their lifespan.

Common Questions About Industrial Anti Fatigue Mats

You've got a handle on materials, sizing, and care. But facility managers often have a few more specific questions. Getting these details right ensures you see the best possible return on your investment in safety and productivity.

Let's tackle the most common questions with direct, practical answers to help you choose with confidence.

How Thick Should an Industrial Anti Fatigue Mat Be?

This is a balancing act. A mat that’s too thin offers no real ergonomic support. But one that's too thick can feel unstable, causing a different kind of fatigue.

For most general industrial jobs, a 5/8-inch (16mm) thick mat is the sweet spot. It provides substantial cushioning without feeling mushy. However, for workstations where an employee is almost completely stationary, stepping up to a 7/8-inch or 1-inch mat can deliver premium comfort.

- Real-World Example: In a busy automotive workshop, a mechanic is constantly moving. A firm 5/8-inch rubber mat is perfect—it gives support but is stable enough for easy movement. Now, consider a quality control inspector who stands in one spot for hours. For them, a softer 7/8-inch polyurethane mat would be a game-changer, providing superior, long-lasting comfort that aids concentration.

Can You Use Anti Fatigue Mats in Wet or Oily Areas?

Yes, absolutely—as long as you use a mat specifically designed for those conditions. A standard, solid-top mat in a wet or oily area is a recipe for disaster, as it traps liquids and creates a dangerous slip hazard.

For these environments, you need the right material and design:

- Material: Choose a mat made from 100% nitrile rubber, which is built to resist industrial oils, greases, and chemicals.

- Design: The mat must have drainage holes. These openings allow liquids to flow through and away from the standing surface, keeping your team on a dry, high-traction platform.

Thinking about a workspace with slick floors? Our comprehensive guide offers 8 things to consider when selecting anti-fatigue mats for wet or slippery surfaces, giving you critical insights for making the safest choice.

- Real-World Example: A metal fabrication shop floor is constantly sprayed with cutting fluids. A solid-top mat would become a slick mess. The only smart solution is a heavy-duty nitrile rubber mat with large drainage holes. This design guarantees fluids pass right through, maintaining a safe, slip-resistant surface for the operators.

When Should We Replace Our Anti Fatigue Mats?

Be proactive. Don't wait for a mat to fall apart. A worn-out mat is no better than concrete and often introduces new hazards. Replace your mats immediately when you spot any of these tell-tale signs:

- Curled Edges: This is the #1 trip hazard. If the edges no longer lie flat, the mat is a liability.

- Cracks or Tears: Rips in the surface trap dirt and signal that the mat's internal structure is failing.

- "Bottoming Out": If you can press down and feel the hard floor right through it, the mat has "dead spots" and no longer provides anti-fatigue relief.

A mat with any of these problems has reached the end of its useful life. Swapping it out promptly is a necessary step to protect your team.

Are Industrial Anti Fatigue Mats a Good Investment?

Without a doubt. They are one of the highest-ROI investments you can make in your people and your operation. The initial cost is paid back quickly through tangible business benefits.

Think about the costs of fatigue: slower output, higher error rates, and increased absenteeism from chronic pain. A single slip-and-fall incident or workers' compensation claim will almost always cost more than outfitting an area with the correct matting from the start.

- The Bottom Line: Industrial anti-fatigue mats are not an expense; they are an investment in a healthier, more focused, and more productive workforce. This investment pays for itself by slashing hidden operational costs and fostering a safer work environment.

Ready to create a safer, more productive workspace? The experts at Mats4U have over 50 years of experience helping businesses find the perfect matting solutions. From heavy-duty industrial mats to custom logo options, we have the right product to meet your needs. Explore our extensive collection and see how the right mat can make all the difference. Visit us at https://www.mats4u.com to get started.