An industrial-grade anti-fatigue mat is a critical piece of safety equipment, but it’s so much more than just a soft place to stand. Think of it as an engineered tool designed to combat the physical toll on workers who spend their days on their feet. These mats provide a cushioned, supportive surface that encourages tiny, constant muscle movements, which in turn boosts blood circulation and drastically reduces the all-too-common pain in the legs, back, and feet.

Why Industrial Anti-Fatigue Mats Are Essential For Your Business

Picture one of your machine operators standing on solid concrete for an eight-hour shift. That hard, unyielding surface forces their leg muscles to lock up and stay static, severely restricting blood flow. This is a direct recipe for physical fatigue, persistent pain, and a sharp decline in concentration—a dangerous combination that increases the risk of accidents and costly mistakes.

An industrial-grade anti-fatigue mat flips this scenario on its head. It acts as a powerful ergonomic intervention. The mat’s cushioned surface is specifically engineered to encourage continuous micro-movements in the legs and calves. This simple, almost unconscious action keeps the muscles gently working, promoting healthy blood flow and preventing the painful stagnation that comes with standing still for hours.

The Clear Business Case For Matting

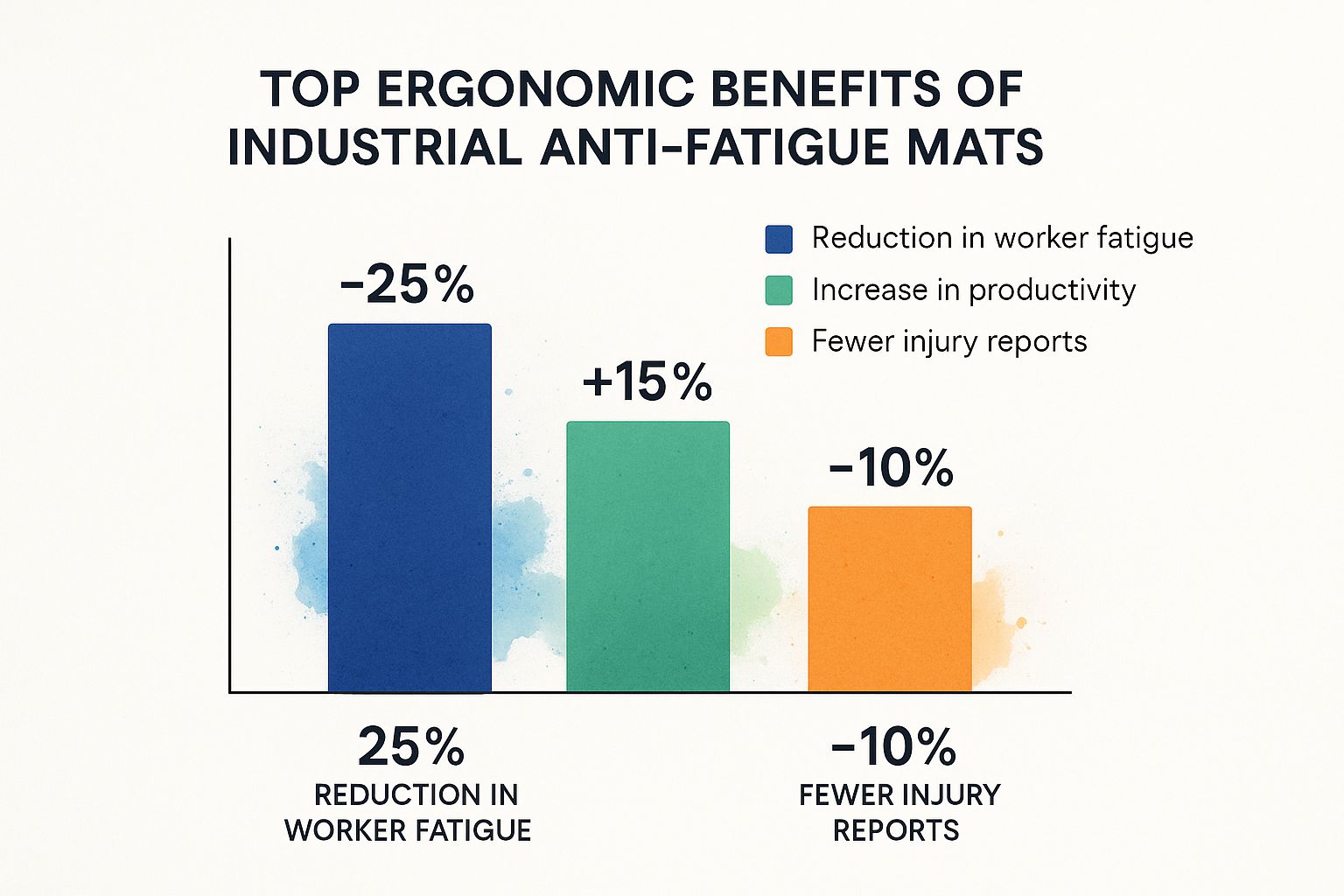

Putting the right matting in place isn't just another expense; it's a strategic investment with a clear and measurable return. By easing the physical strain on your team, you unlock tangible business benefits that directly boost your bottom line.

-

How-To Benefit: Reduce direct and indirect health costs by preventing Musculoskeletal Disorders (MSDs).

- Actionable Strategy: Place ergonomic matting at all standing workstations, especially those where employees remain for over two hours at a time. This directly tackles the root cause of many lower back and joint issues, which are leading drivers of workers' compensation claims.

-

How-To Benefit: Improve attendance and engagement by minimizing chronic pain.

- Actionable Strategy: Conduct a survey to identify workstations with the highest reports of physical discomfort. Prioritize mat installation in these "hot spots" first to show employees their well-being is a priority, leading to better morale and reduced absenteeism.

-

How-To Benefit: Boost productivity and focus by eliminating pain-related distractions.

- Actionable Strategy: Implement a pilot program with anti-fatigue mats on one production line. Track key metrics like output per hour and error rates. The resulting data will demonstrate that a comfortable worker is a more focused, accurate, and efficient worker.

The market is certainly taking notice of these ergonomic benefits. Projections show the industrial anti-fatigue mat market is set to grow from USD 1.52 billion in 2024 to an estimated USD 2.78 billion by 2033. This surge is driven by the undeniable need to improve worker well-being and safety, especially when you consider that over 20% of workplace injuries come from slips, trips, and falls—a risk that quality matting also helps to minimize.

Real-World Example: A mid-sized manufacturing plant rolled out industrial anti-fatigue mats at all of its assembly line workstations. Within just six months, they recorded a 30% drop in reported leg and back pain from staff and saw a significant decrease in production errors during the last two hours of every shift, directly improving their end-of-day output.

At the end of the day, the link between physical comfort and operational excellence is impossible to ignore. To get a more detailed look at the specific health benefits, we invite you to explore our guide on anti-fatigue mats and your health. It’s a small change to the work environment that can lead to major improvements in safety, morale, and overall efficiency.

Choosing the Right Mat Material for Your Workspace

Picking the right industrial anti fatigue mat isn't a one-size-fits-all deal. It's a decision that goes far deeper than just comfort. The actual material your team stands on is every bit as important as the cushioning it provides, and getting it wrong can mean wasted money, a mat that falls apart in months, or even a brand-new safety hazard.

Think of it like choosing the right tires for a vehicle. You wouldn't put standard road tires on a truck that operates in a quarry. In the same way, the mat you choose must be perfectly matched to its environment, standing up to everything from chemical spills to the constant rumble of cart traffic.

Investing in proper matting directly impacts your bottom line through reduced fatigue, better productivity, and fewer injury reports. This is a strategic investment where the right material choice is your first step to success.

Matching Industrial Mat Materials to Workplace Conditions

Here is a practical, actionable guide to the most common materials and where they perform best. Use this breakdown to find a mat that not only delivers comfort but is built to last in your specific conditions.

| Material | Best For (Environment) | Key Strengths | Primary Weaknesses | How to Apply This Knowledge |

|---|---|---|---|---|

| Nitrile Rubber | Oily, greasy, and chemical-heavy areas | Excellent resistance to petroleum-based fluids and chemicals. Very durable. | Higher initial cost. Can be heavier than other options. | Example: At an automotive repair shop, place nitrile mats in service bays. They won't degrade from contact with engine oil or transmission fluid, ensuring a safe, non-slip surface that lasts for years. |

| Polyurethane | High-traffic dry areas | Exceptional durability and crush resistance. Resilient and long-lasting. | Not ideal for areas with heavy oil or chemical exposure. | Example: For a busy warehouse fulfillment center, use polyurethane mats at packing stations. They can withstand constant foot traffic and the weight of workers all day without flattening out. |

| PVC / Vinyl | General-purpose, dry environments | Cost-effective and versatile for basic applications. Lightweight. | Prone to cracking and curling with chemical exposure. Wears faster under heavy use. | Example: In a light assembly area where workers handle electronics, a simple PVC mat provides the necessary comfort without the high cost of a chemical-resistant mat, making it a budget-smart choice. |

Choosing the right material is the first and most critical step. As you can see, a PVC mat in a machine shop is a recipe for disaster, while a heavy-duty nitrile mat might be overkill for a simple packing station.

Don't Overlook These Critical Design Features

Beyond the core material, a few key design features can make or break a mat's effectiveness and safety profile in a tough industrial setting.

-

Beveled Edges: These sloped borders are non-negotiable for safety.

- Benefit: They prevent trip hazards and allow carts to roll over smoothly.

- Example: In a distribution center, mats with low-profile, beveled edges allow pallet jacks to move on and off the matted area without snagging, preventing dangerous tip-overs and workflow interruptions.

-

Drainage Holes: Essential for any area where liquids are present.

- Benefit: They keep the standing surface drier and more slip-resistant.

- Example: In a commercial kitchen, mats with drainage holes allow water, grease, and food debris to fall through, keeping the chefs' standing surface clear and drastically reducing the risk of a slippery fall.

-

Surface Texture: The grip on the top of the mat is crucial.

- Benefit: An aggressive texture provides better footing and reduces slips.

- Example: In a metal fabrication shop where cutting fluids can create slick spots, a mat with a raised, diamond-plate texture gives workers the secure grip needed to operate machinery safely.

For a deeper look at all the options, you can explore our complete guide to industrial anti-fatigue mats. By carefully matching the material and design to your specific needs, you'll ensure your investment actively contributes to a safer, more comfortable, and more productive workspace.

A Practical Framework for Selecting Your Mat

Choosing the right anti fatigue mat industrial grade isn't about guesswork. To get it right, you need a smart, practical approach that ensures your investment pays off in safety and productivity. When you replace assumptions with a clear framework, you can confidently pick a mat that’s a perfect fit for the job.

The global market for these mats was valued at USD 1.80 billion in 2023 and is on track to hit USD 3.09 billion by 2034, according to a report from Precedence Research. This growth shows that companies everywhere are recognizing these mats as essential safety gear. Here's how to make the right choice for your facility.

Step 1: Audit Your Workstation and Define Needs

First, perform a simple but vital audit of the exact spot where the mat will live. Think of yourself as a detective at your own workspace, looking at the entire workflow.

Your Actionable Audit Checklist:

- Observe the Task: Is it stationary assembly, packing, or operating machinery?

- Time the Standing: Is it a full eight-hour shift or shorter, intermittent periods?

- Track the Traffic: Do heavy carts, dollies, or pallet jacks need to roll over the mat?

- Identify Hazards: Look for oils, chemicals, water, metal shavings, or static electricity.

This audit builds a detailed profile of what the workstation demands. Your answers create a checklist of non-negotiable features, like chemical resistance, low-profile edges for cart access, or anti-static properties to protect sensitive electronics.

Real-World Example: A warehouse manager needs to outfit five packing stations. Her audit reveals workers stand for their entire shift and rolling carts constantly bring products to the tables. This immediately tells her she needs a durable mat with heavily beveled, low-profile edges. This prevents a trip hazard and allows carts to roll smoothly, solving two problems with one product choice.

Step 2: Match Mat Thickness and Size to the Task

Once you know what you need the mat to do, you can focus on its physical specs. When it comes to mat thickness, "more is better" isn't always true. It’s all about finding the sweet spot of support.

How to Choose the Right Thickness:

- For lighter workers or shorter standing periods (under 4 hours): A standard 1/2-inch thickness often provides sufficient support.

- For heavier workers or full-shift standing: A thicker mat, around 7/8-inch to 1-inch, delivers more substantial cushioning to fight fatigue over long hours.

A mat that’s too soft can be just as bad as concrete, causing instability. The real goal is firm, consistent support.

How to Choose the Right Size:

- For a single workstation: Measure the area to ensure the mat is large enough for the worker to move around comfortably without stepping off the edge.

- For long assembly lines: Use interlocking modular tiles. These can be configured to create a continuous, seamless surface, eliminating gaps that cause trips.

This methodical approach is the key to landing the perfect anti fatigue mat industrial solution for your team.

Protecting Your Investment with Proper Mat Care

An industrial anti-fatigue mat is a serious asset, but like any tool, its performance depends on proper care. A well-maintained mat does its job day in and day out. A neglected one can quickly degrade, losing its ergonomic benefits and even becoming a safety hazard.

Protecting this investment starts with proper installation and a simple, consistent maintenance routine.

Actionable Tip for Installation: Before laying down any mat, ensure the floor underneath is completely clean, dry, and free of debris. Trapped moisture can breed mold, and debris can cause the mat to wear out from underneath. For modular tiles, ensure all connections are secure to create a seamless surface without trip-causing gaps.

A Practical Maintenance Checklist For Longevity

Consistent care is the secret to getting the most life and performance out of your anti fatigue mat industrial solution. A simple but regular cleaning schedule is your best defense against premature wear.

Here’s a straightforward, actionable checklist you can implement immediately:

- Daily Sweep or Dry Mop: Remove loose dirt, dust, and debris. This quick daily task prevents abrasive particles from being ground into the mat's surface, which causes significant damage over time.

- Weekly Deep Clean: Use a deck brush and a manufacturer-approved mild detergent to scrub the mat. This is critical in areas like machine shops where grease and grime build up quickly.

- Rinse and Dry Thoroughly: After washing, rinse the mat completely with clean water and allow it to air dry fully before putting it back in service. Propping it up or hanging it will speed up the process.

Real-World Example: A food processing facility implemented a mandatory weekly deep-cleaning protocol for their wet-area anti-fatigue mats. By staying on top of grease and organic buildup, they not only maintained better hygiene—they doubled the effective lifespan of their mats, pushing back a costly replacement cycle and saving thousands of dollars.

How To Spot Early Signs of Wear

Even with the best care, all mats have a finite lifespan. Knowing when to replace a mat is just as crucial as knowing how to clean it.

Actionable Triage Checklist - Replace the Mat If You See:

- Curled or Cracked Edges: The beveled edges must lie perfectly flat. If they are curled or cracked, the mat is a serious trip hazard and must be replaced immediately.

- Visible Compression: Look at the high-traffic spots. If you see permanent dents or the mat feels flat and unresponsive, it has lost its cushioning power and its ergonomic benefit is gone.

- Surface Damage: Scan for any rips, tears, or punctures. These compromise the mat's integrity and can trap debris, making it unsafe.

For a deeper dive into mat longevity, learn more about how long anti-fatigue mats last. Replacing a worn-out anti fatigue mat industrial grade isn't an expense—it's a non-negotiable part of protecting your team.

Advanced Mat Features That Solve Specific Problems

A modern anti fatigue mat industrial grade does much more than provide comfort. Think of it as a multi-tool engineered to solve very specific problems on your factory floor. These advanced features elevate a simple ergonomic aid into a strategic asset that can boost quality control, enhance safety, and support highly specialized production.

Solving Invisible Threats Like Static Discharge

In facilities handling delicate electronic components, electrostatic discharge (ESD) is a constant, invisible threat. A single, undetectable spark can destroy thousands of dollars worth of sensitive electronics. This is where anti-static mats become non-negotiable.

How They Work: Anti-static (ESD) mats are designed to safely and continuously drain static electricity from a worker before it can build up. They use conductive materials to channel the charge away to a proper grounding point, creating a safe zone for mission-critical tasks.

Real-World Example: An electronics assembly plant was struggling with a high rate of product failure during final testing. An audit revealed the culprit was static discharge from workers. Actionable Solution: They replaced standard mats with a fully integrated anti fatigue mat industrial ESD system at every workstation. Result: They slashed product defects by 18% within three months, saving thousands in rework and scrap.

Specialized Mats for Unique Environments

Different industrial settings have their own unique challenges, and the matting industry has stepped up with targeted solutions.

Here are examples of specialized features and how to use them:

-

Conductive Matting: For highly sensitive environments like cleanrooms or munitions handling areas where even a hint of static is unacceptable.

- Benefit: Provides rapid and total discharge of static electricity for maximum protection.

-

Antimicrobial Properties: For food processing, pharmaceutical labs, or healthcare settings where hygiene is paramount.

- Benefit: The mat surface is infused with agents that actively inhibit the growth of bacteria and mold, contributing to a more sterile workspace.

-

High-Visibility Borders: For busy production floors or warehouses.

- Benefit: Mats with bright, OSHA-approved yellow or orange borders provide ergonomic support while clearly marking safe walkways and work zones, enhancing situational awareness and preventing accidents. See more on this in our guide to industrial non-slip mats.

The global anti-fatigue mats market was valued at an estimated USD 19.4 billion in 2024 and is projected to climb to USD 32.1 billion by 2034. This boom is fueled by demand for mats that do more than just cushion. You can explore more details about these market trends here. When you choose a mat with advanced features, you're investing in a solution tailor-made for your most critical needs.

Got Questions About Industrial Anti-Fatigue Mats? We've Got Answers.

Even after you've done your research, practical questions always pop up when you're about to invest in a new matting solution. Getting straightforward answers is the final step in making sure you choose the right mat and get the most from it. Let's tackle some of the top questions we hear from facility and safety managers.

How Thick Should an Anti-Fatigue Mat Be?

The ideal thickness depends on the duration of standing and the worker's weight. It’s about finding the right balance of comfort and support.

Actionable Guide to Thickness:

- For shorter shifts (under 4 hours) or lighter-weight workers, a standard 1/2-inch mat provides excellent support.

- For full 8-hour shifts or heavier workers, a thicker mat in the 7/8-inch to 1-inch range offers superior cushioning to combat serious fatigue.

The Goal: The aim is optimal support, not maximum softness. A mat that is too squishy can cause instability and throw off a worker's balance. The right mat feels supportive and firm underfoot.

Can We Roll Carts or Use Chairs on These Mats?

This is a critical question for dynamic workspaces, and the answer depends entirely on the mat's material and construction.

How to Choose a Mat for Mixed Use:

- Avoid: Standard foam mats will be quickly damaged by the focused pressure of chair legs or rolling carts.

- Choose: For these environments, you need a high-density rubber or solid polyurethane mat. These are engineered for this kind of mixed-use.

Real-World Example: A busy fulfillment center with standing packers and rolling carts requires a mat that can handle both. The Solution: A solid, high-density polyurethane mat with a low-profile, crush-resistant design. This allows carts to glide over the surface without snagging, protecting both the mat and the workflow.

How Do I Know When It's Time to Replace a Mat?

Knowing when to retire a mat is a vital part of your safety protocol. A worn-out mat is no longer an asset; it's a liability.

Use This Simple Inspection Checklist:

- Check the Edges: Are they curled, cracked, or no longer flat? If yes, it's a trip hazard. Replace it.

- Test the Cushioning: Can you see permanent dents where people stand? Does it feel flat and dead? If yes, the ergonomic benefit is gone. Replace it.

- Inspect the Surface: Are there any rips, tears, or deep gashes? If yes, its integrity is compromised. Replace it.

What's the Real Difference Between Industrial and Commercial Mats?

The main difference is durability and resistance. An industrial anti fatigue mat is a workhorse, engineered to survive harsh environments. It's built to withstand heavy use, chemical spills, and extreme temperatures.

Example Application: A commercial-grade mat is perfect for a hotel check-in desk but would quickly fail in a welding shop where it would be exposed to sparks and metal shavings. The industrial mat for that same welding shop would be made of heavy-duty rubber designed to resist high heat and punctures.

Ready to find the perfect matting solution to boost safety and productivity in your facility? The experts at Mats4U can help you select the ideal mat for any industrial application. Explore our complete collection and get a durable, high-performance solution delivered right to your door.

Shop our full range of industrial and commercial mats at Mats4U.com