You wouldn't use a bathmat in a busy factory workshop, would you? Of course not. Industrial non-slip mats aren't just floor coverings; they are engineered safety systems designed to prevent costly accidents and keep your operations running smoothly.

In demanding environments where oils, water, or debris are part of the daily routine, these mats provide a high-traction surface that dramatically reduces the risk of slips, trips, and falls. This guide shows you how to select, implement, and maintain the right mats to transform your facility's safety and efficiency.

How Smart Facilities Benefit from Industrial Non-Slip Mats

Think of your facility's floor as the foundation of its safety and productivity. If that foundation is slick, everything built upon it is at risk. This is why investing in high-quality industrial non-slip mats is a smart, proactive move. It’s not about ticking a compliance box; it's about delivering a measurable return by protecting your most valuable asset—your team.

These mats directly counter common workplace hazards. By providing stable, high-grip surfaces, you can prevent the very accidents that lead to downtime, painful insurance claims, and hefty regulatory fines.

Step 1: Build a Foundation for Safety and Compliance

Your first and most immediate win will be a sharp drop in slip-and-fall incidents. These aren't minor mishaps; they represent a huge financial and operational liability for any business.

Actionable Takeaway: By preventing even a single serious injury, a high-quality matting system can pay for itself many times over. This transforms it from an operational expense into a critical safety investment.

Taking this proactive stance is key to meeting regulatory standards, like those set by OSHA for safe walking-working surfaces. Non-compliance can lead to steep penalties, but it's often the indirect costs of an accident—like lost productivity, plummeting morale, and soaring insurance premiums—that hurt the most.

The market is catching on. The growing anti-slip mat market reflects this shift as more businesses get serious about safety. When you consider that slips, trips, and falls are responsible for about 27% of all workplace injuries, the need for action becomes clear.

Step 2: Unlock Tangible Returns Beyond Accident Prevention

The benefits of placing the right mats go far beyond safety. A well-chosen mat can also boost productivity and trim operational costs in surprising ways. Here’s how you can leverage them:

-

Improve Employee Comfort: For workers who stand all day, anti-fatigue non-slip mats are a game-changer.

- How-To: Place cushioned anti-fatigue mats at standing workstations, like assembly lines or packing tables.

- Benefit: The cushioning reduces joint and muscle strain, leading to less fatigue, sharper focus, and fewer errors during long shifts.

-

Reduce Cleaning Costs: High-performance entrance and scraper mats act as your facility's first line of defense.

- How-To: Position aggressive scraper mats at every exterior entrance.

- Benefit: They trap dirt, debris, and moisture at the door. Less mess tracked inside means lower cleaning bills and labor costs.

-

Protect Your Assets: Mats act as a shield for your expensive flooring.

- How-To: Use heavy-duty mats in areas with high foot traffic, dropped tools, or chemical spills.

- Benefit: They absorb impact and spills, protecting your floors from damage and extending their lifespan.

To bring this all together, here is the clear business case for using high-performance matting.

The Business Case for High-Performance Matting

| Benefit | How to Achieve It | Real-World Example & Impact |

|---|---|---|

| Drastic Injury Reduction | Place appropriate non-slip mats in areas with known slip hazards (e.g., wet, oily, or dusty zones). | A manufacturing plant places nitrile mats in oily production areas. Benefit: Slip-related incidents drop by over 50%, reducing workers' comp claims. |

| Enhanced Productivity | Install anti-fatigue mats at all standing workstations. | Assembly line workers stand on cushioned mats. Benefit: They report less back and leg pain, leading to a 10% increase in output during long shifts. |

| Lower Maintenance Costs | Use scraper and entrance mats at all doorways leading from outside. | A warehouse places scraper mats at all entry points. Benefit: The facility cuts its floor cleaning budget by 20% due to less tracked-in dirt and moisture. |

| Regulatory Compliance | Conduct a risk assessment and place mats to meet OSHA standards for safe walking surfaces. | A food processing facility installs compliant matting. Benefit: It passes a surprise OSHA inspection, avoiding fines and operational disruptions. |

| Floor & Asset Protection | Use heavy-duty mats in workshops and high-traffic corridors. | A mechanic's workshop uses heavy-duty mats that absorb oil spills and tool impacts. Benefit: The shop saves thousands on concrete floor repairs. |

It's clear that the right matting is more than just a purchase; it's a strategic investment in the health of your business and your team.

Real-World Example: In a bustling commercial kitchen, spills are constant—water, grease, food—creating a slippery floor. The kitchen manager installs grease-resistant, non-slip rubber mats with drainage holes.

- Outcome 1 (Safety): The risk of a dangerous fall plummets.

- Outcome 2 (Productivity): Chefs, who are on their feet for hours, now have a comfortable anti-fatigue surface, reducing strain and improving focus. With one smart investment, the manager improved safety, boosted staff morale, and kept the kitchen running productively and in full compliance. That’s the power of the right mat.

How to Choose the Right Mat for Your Workspace

Not all industrial floors face the same challenges. A welding shop’s floor endures hot slag, while a food processing line battles constant moisture. Choosing the right industrial non-slip mats isn't about finding a one-size-fits-all solution; it’s about matching the mat's features to your specific workspace hazards.

Think of it like choosing tires. You wouldn't put racing slicks on a truck heading for muddy trails. Similarly, a generic mat will fail in a demanding industrial setting, creating a new safety risk. The key is to analyze your environment first.

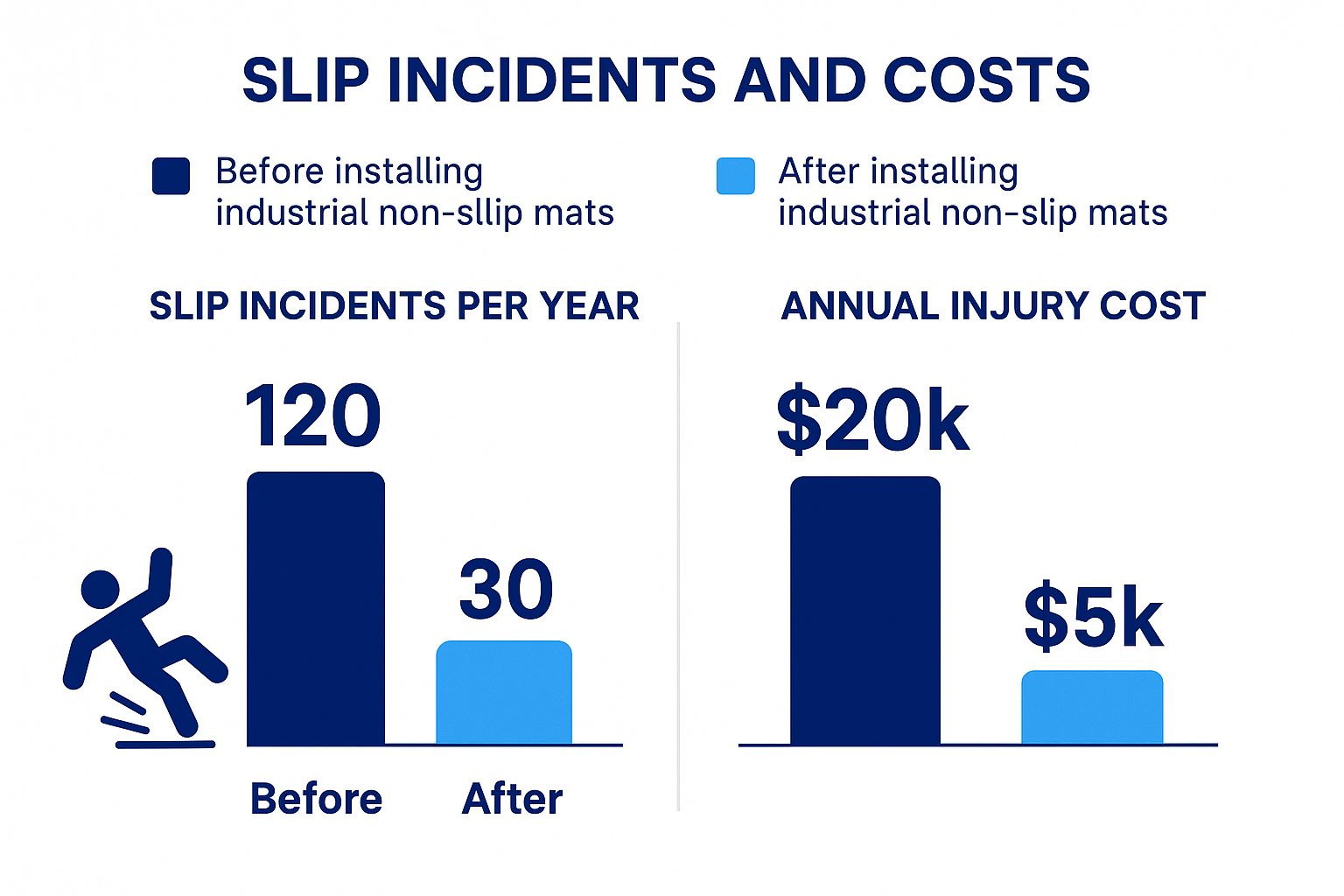

The data clearly shows that a strategic investment in appropriate matting can cut accidents by 75% and slash injury costs, delivering a powerful return on your safety investment.

Action Step: Match the Mat to the Hazard

To make the right choice, start by identifying your primary challenge. Are you dealing with water, oils, grease, or debris from heavy foot traffic? Each scenario demands a different type of mat. Choosing the right material is the most critical step. Get this wrong, and even the best-designed mat will fail.

Here’s a quick comparison to help you select the correct material for your needs.

Comparing Industrial Mat Materials and Their Best Uses

| Material Type | Key Properties | Best For (How to Use It) | Avoid Using In |

|---|---|---|---|

| Nitrile Rubber | Oil/grease-proof, chemical resistant, durable | Automotive shops, industrial kitchens, and manufacturing areas where petroleum-based fluids are present. | General-purpose dry areas where its chemical resistance is not needed (overkill). |

| Natural Rubber | Excellent grip, flexible, good fatigue relief | Dry assembly lines, standing workstations, and general-purpose areas needing comfort and grip. | Oily or greasy environments, as oils will cause it to break down. |

| Vinyl (PVC) | Lightweight, chemical resistant, cost-effective | Wet areas like showers and pools, or labs with non-petroleum chemical spills. | Oily areas or high-temperature zones, which cause it to degrade. |

| Polypropylene | Dries quickly, stain/fade resistant, good scraper | Outdoor entrances and high-moisture indoor entryways to scrape shoes and absorb water. | Heavy-duty industrial settings with chemical or oil exposure. |

This table is your starting point. Always match your specific workplace hazards with the material's properties to ensure a safe and effective choice.

Solutions for Common Industrial Hazards

Here is how to solve specific problems with the right mat:

-

Problem: Oily and Greasy Areas. Standard rubber or vinyl mats will warp, become slick, and fall apart when exposed to petroleum products.

- Solution: You need mats made from 100% nitrile rubber. Nitrile is engineered to resist oils and grease, so it maintains its shape and grip where other materials fail.

- Real-World Example: An auto repair garage places nitrile rubber mats in every service bay. Benefit: Mechanics gain secure footing even with transmission fluid or oil spills, preventing dangerous falls and letting them focus on their work.

-

Problem: Constant Wetness. In places like commercial kitchens, wash-down stations, or food processing plants, water is a constant hazard.

- Solution: The best wet area mats feature large drainage holes and a raised surface. This design allows water to flow through and away from the standing surface, keeping feet dry and secure.

- Real-World Example: A beverage bottling plant installs flow-through mats along its main production line. Benefit: This prevents water from pooling, drastically reduces slip hazards, and makes cleanup at the end of each shift much easier and faster.

Addressing Comfort and Cleanliness

Beyond acute slip hazards, the right mat can tackle issues that impact productivity and maintenance.

Actionable Takeaway: Choosing a mat is an operational decision. The right one not only boosts safety but also supports worker well-being and reduces long-term maintenance costs.

-

Anti-Fatigue Mats for Standing Workstations: For assembly lines or packing stations, anti-fatigue mats are essential. These mats have a cushioned surface that reduces strain on the back, legs, and feet. We have a whole guide that explores what anti-fatigue mats are if you want to learn more about the science behind them.

-

Heavy-Duty Entrance Mats: Your first line of defense against tracked-in dirt is a robust entrance mat. Scraper mats are designed to aggressively remove debris from shoes. This simple step keeps your interior floors cleaner and safer for everyone.

Essential Features of a High-Performance Safety Mat

What separates a top-tier industrial non-slip mat from a cheaper one that fails when you need it most? It’s not just the price. A few critical engineering features determine if a mat is a reliable safety tool or just another hazard.

Knowing what to look for helps you see how a mat will actually perform on your floor. It’s the difference between a temporary patch and a long-term safety investment. Think of a great mat as a complete system, where every part works to keep your team safe.

Material Composition: The Bedrock of Performance

The most important factor is what the mat is made of. This dictates its durability, chemical resistance, and lifespan. For example, nitrile rubber is the champion for areas with oils, grease, or chemicals. Unlike cheaper PVC or natural rubber that can absorb these fluids and curl at the edges, nitrile holds its shape and stays effective.

How to get it right: Before buying, list all chemicals and fluids the mat will be exposed to. Match this list against the manufacturer's specifications to ensure the material is compatible. If you place a mat made from the wrong material in a demanding environment, it will become a new trip and slip hazard.

Surface Design and Drainage Channels

A mat’s surface is like the tread on a high-performance tire. A mat's surface pattern is engineered to grip footwear.

The best industrial non-slip mats have aggressive, raised textures that create high-traction points. In wet or oily conditions, this design needs a partner:

- Drainage Holes: These are non-negotiable for wet areas. They let water, oils, and coolants flow through the mat instead of pooling on top.

- Raised Base: Many premium mats are built on small knobs that lift the mat off the floor. This creates a channel underneath for liquids to drain away.

Real-World Example: Imagine a food processing plant where floors are constantly hosed down. A solid-surface mat would trap water, creating a slick "aquaplaning" effect. But a mat with large drainage holes and a raised base lets water flow underneath, keeping the top surface consistently slip-resistant and workers safe.

To see these designs, you can explore various anti-slip floor mats and see how their features are tailored to specific industrial uses.

Beveled Edges: A Critical Safety Detail

Finally, never overlook the edges. A high-quality mat will always have beveled or sloped edges on all sides. This might seem like a small detail, but it’s critical for safety.

This design creates a smooth ramp from the floor to the mat, which is essential for preventing trips, especially where people are moving fast or pushing carts. A blunt, 90-degree edge is a major, yet avoidable, trip hazard. An effective safety mat solves one problem without creating another.

How to Meet OSHA Compliance and Ensure Workplace Safety

Meeting safety regulations isn't optional. The Occupational Safety and Health Administration (OSHA) has clear standards for safe walking surfaces. The right industrial non-slip mats are one of the most direct and effective tools you have to stay compliant and turn high-risk zones into secure ground for your team.

Think of mats as a proactive risk management strategy. When you install certified, high-traction mats, you're building a defense against costly fines, legal headaches, and skyrocketing workers' compensation premiums.

Action Step: Conduct a Simple Slip Risk Assessment

To get the most out of your mats, first pinpoint your facility's danger zones. A simple "slip risk assessment" will do the trick. Walk through your workspace and look for areas where a slip is waiting to happen.

Here’s a quick checklist of where to look:

- [ ] Loading Docks: Exposed to rain, snow, and moisture from outside.

- [ ] Production Lines: Zones with frequent spills of liquids, oils, or fluids.

- [ ] Transition Areas: Spots where floor surfaces change (e.g., concrete to tile).

- [ ] Wash-Down Stations: Locations that are frequently wet from cleaning.

- [ ] Kitchens & Breakrooms: Areas prone to food and drink spills.

This quick audit gives you a practical map, showing you exactly where an investment in industrial non-slip mats will deliver the biggest safety payoff.

Actionable Takeaway: A smart matting strategy isn't about just tossing a mat down. It's about putting the right mat in the right place to solve a specific safety problem and satisfy regulatory demands.

Connecting Mats to Financial and Legal Protection

Once you’ve mapped these high-risk zones, the link between matting and compliance becomes clear. OSHA mandates that employers keep floors clean and dry. In busy industrial settings where that isn’t always possible, providing a high-traction surface is essential.

Real-World Example: A metal fabrication shop was cited by OSHA for slip hazards in its cutting area, where coolant regularly splashed onto the concrete floor.

- The Fix: They installed heavy-duty, oil-resistant mats with drainage channels.

- The Result: The shop not only satisfied the citation but also documented a 40% reduction in minor slip incidents within three months. That one change made the work environment tangibly safer and got regulators off their back.

Investing in compliant matting is a strategic move to insulate your business from liability. To better understand how different mats contribute to your safety program, review this comprehensive guide on floor safety mats.

How to Protect Your Investment with Proper Mat Care

Think of an industrial non-slip mat as a high-performance safety tool. Like any critical equipment, its effectiveness depends on its condition. Regular care isn't about looks—it's about ensuring it can do its job for years.

When maintenance slides, a safety asset can quickly become a hazard. A mat caked with grime can't provide the grip it was designed for. By setting up a simple care routine, you protect your investment and give your team a reliable, safe surface to work on.

A Practical Cleaning Schedule

Creating a maintenance plan is easy. Just break it down into daily, weekly, and monthly tasks to keep your industrial non-slip mats in peak condition.

Daily Check (Less than 5 minutes):

- Action: Give the mat a quick sweep or brush-down to clear away loose dirt, dust, and debris.

- Benefit: This stops abrasive particles from being ground into the surface, which preserves the mat's texture and ensures daily safety.

Weekly Wash (10-15 minutes):

- Action: Move mats to a wash area. Use a deck brush and a mild, manufacturer-approved detergent to scrub the surface. Rinse thoroughly with a hose.

- Benefit: This removes built-up grime and oils that a sweep can't, restoring the mat’s grip.

Monthly Inspection (15-20 minutes):

- Action: Give each mat a detailed inspection. Check for curled edges, cracks, splits, or spots where the non-slip texture has worn smooth.

- Benefit: This proactive check helps you identify mats that are at the end of their life before they become a trip or slip hazard.

For a more detailed routine, this comprehensive guide on floor mat cleaning is a great resource.

Common Maintenance Mistakes to Avoid

Knowing what not to do is just as important. The wrong cleaning methods can do more harm than good.

Critical Mistake: Using harsh chemicals like industrial degreasers or bleach. These substances break down rubber and vinyl, leaving mats brittle, cracked, and dangerously slick.

Steer clear of these errors:

- Using High-Pressure Washers: A pressure washer on a high setting can strip the textured surface off the mat, destroying its non-slip properties. Use low pressure only.

- Ignoring a Mat’s Underside: Clean and dry the bottom of the mat and the floor beneath it. Trapped moisture leads to mold and a slippery film that can cause the entire mat to slide.

Real-World Example: A machine shop started using an aggressive citrus degreaser on their nitrile rubber mats. Within weeks, the mats became stiff and the edges curled up, creating a major trip hazard. The lesson: The cost of replacing the ruined mats was far greater than any time saved on cleaning.

Your Smart Buyer's Checklist for Industrial Mats

Choosing the right industrial non-slip mat is simpler when you know what to look for. Use this checklist to ask the right questions and ensure the mat you pick is a perfect fit for your facility's real-world demands. This isn’t just about buying a mat; it’s about implementing a safety solution that works.

Step 1: Environment and Exposure Analysis

First, get a clear picture of the environment where the mat will be used.

-

What substances will it encounter? Be specific: water, hydraulic fluids, industrial cleaners, cutting oils, or animal fats? A mat that handles water might fail when it meets grease.

- Practical Example: In a food processing plant, you need mats that handle water and organic waste, making a nitrile mat with drainage ideal. In an auto shop, you need 100% nitrile rubber to stand up to petroleum-based fluids without warping.

-

What's the traffic like? Assess both the volume and type. Is it just foot traffic, or does it need to withstand heavy carts or even forklifts? A light-duty mat will be destroyed in a heavy-traffic area.

Step 2: Functionality and Safety Features

Next, zero in on the features that protect your team and make their jobs easier.

Actionable Insight: A mat's design features are not "nice-to-haves"; they are the core of its function as a safety tool. Overlook them, and you’re choosing an incomplete solution.

Ensure the mat you choose is built for the job:

- Are anti-fatigue properties needed? For stations where people stand for hours (e.g., assembly lines, packing areas), mats with ergonomic cushioning are a must to reduce physical strain and keep your team focused.

- Do the edges prevent trips? This is critical. Always look for beveled, sloped edges. A mat with a blunt, 90-degree edge is a trip hazard waiting to happen, defeating the purpose of a safety mat.

- What are the cleaning requirements? Be realistic. Can your team handle a mat that needs a daily scrub-down, or do you need a low-maintenance option? The best mat is the one your team can consistently maintain.

Frequently Asked Questions About Industrial Mats

Getting straightforward, practical answers is key to choosing the right mat for your facility. Here are some of the most common questions we encounter.

How Often Should We Replace Our Industrial Non-Slip Mats?

There’s no fixed timeline. A mat’s lifespan depends on foot traffic, environmental exposure (like chemicals), and material quality. Instead of using a calendar, train your team to recognize the signs of wear.

Proactive Tip: A mat that is visibly worn is no longer a safety asset—it's a liability.

Make it a habit to inspect mats in high-traffic zones quarterly. Look for these red flags that mean it's time for a replacement:

- Curled or Cracked Edges: These are active trip hazards.

- Visible Wear Patterns: If the non-slip texture is worn smooth, the mat has lost its grip.

- Loss of Integrity: The mat feels flimsy, has cracks, or won't lie completely flat.

As a general guideline, plan to replace mats in your busiest areas every 1 to 3 years to maintain peak safety.

Are More Expensive Mats Worth the Cost?

It’s tempting to choose the cheaper option, but with industrial mats, think long-term value, not initial price. A higher upfront cost for an industrial non-slip mat usually means superior materials and smarter engineering.

Here's how to think about it: A premium 100% nitrile rubber mat will easily outlast a cheaper PVC-blend mat in an oily machine shop. The cheaper mat might seem like a win initially, but it will quickly break down, forcing you to replace it more often and creating a serious safety risk in the meantime.

When you invest in a durable, well-made mat with features like beveled edges and proper drainage, you get a lower total cost of ownership and, more importantly, a genuinely safer workplace.

Ready to create a safer, more productive environment? The team at Mats4U has over 50 years of experience helping facilities like yours find the perfect matting solutions. Explore our extensive collection of high-performance industrial non-slip mats at https://www.mats4u.com and get a free quote today.