In today's competitive landscape, managing a facility extends far beyond simply keeping the lights on and the floors clean. It has evolved into a strategic function crucial for creating environments that are safe, efficient, sustainable, and productive. Yet, many managers find themselves caught in a cycle of reactive problem-solving, constantly battling unexpected equipment downtime, escalating operational costs, and inefficiently utilized spaces. This reactive approach not only drains resources but also prevents the facility from becoming a true strategic asset that supports broader organizational goals.

This article is designed to break that cycle. We will explore seven proven facility management best practices that shift your operational approach from reactive firefighting to proactive, strategic planning. Each practice represents a pillar of modern operational excellence, offering a clear roadmap with actionable steps and real-world examples to guide implementation. From leveraging integrated technology for streamlined oversight to implementing robust preventive maintenance schedules that predict failures before they happen, you will gain tangible insights.

You'll learn how to transform your facility into a high-performing asset that directly contributes to your organization's bottom line. The strategies outlined here will empower you to enhance safety, reduce long-term expenses, improve occupant satisfaction, and align your facility's performance with key business objectives. Let's dive into the essential practices that will unlock a new level of efficiency and value within your buildings.

1. Integrated Workplace Management Systems (IWMS)

In an era where data drives decisions, managing complex facilities with disconnected spreadsheets and siloed software is no longer viable. An Integrated Workplace Management System (IWMS) is a powerful, centralized software platform that consolidates all core facility management functions into a single, unified interface. This approach provides a "single source of truth" for everything from space utilization and maintenance scheduling to real estate portfolio management and sustainability tracking.

By integrating disparate data streams, an IWMS empowers facility managers to move from reactive problem-solving to proactive, data-driven strategy. This is a cornerstone of modern facility management best practices, as it transforms raw data into actionable intelligence, streamlining workflows and revealing opportunities for significant cost savings and operational improvements across an entire real estate portfolio.

How an IWMS Drives Efficiency

An IWMS platform typically combines several key modules into one cohesive system. This integration allows for seamless communication between departments and functions that would otherwise operate independently.

- Space Management: Visualize floor plans, track occupancy, and optimize layouts to reduce wasted space. For example, a large financial firm can use its IWMS to identify that the third floor is only at 40% occupancy on Fridays. They can then implement a "hoteling" desk system and consolidate teams, ultimately allowing them to sublease the entire floor and generate revenue.

- Maintenance Operations: Automate work order creation, schedule preventive maintenance, and track asset performance. A hospital can use an IWMS to automatically generate a work order for an HVAC unit when its performance data trends outside of normal parameters, preventing a critical failure in a patient care area.

- Real Estate & Lease Management: Manage lease agreements, track critical dates, and analyze portfolio performance to make informed buy, sell, or lease decisions. A retail chain can receive automated alerts 90 days before a lease expires, giving them ample time to negotiate renewals or plan a relocation.

- Sustainability & Energy Tracking: Monitor utility consumption, track environmental performance metrics, and identify opportunities to reduce an organization's carbon footprint. A university campus can use the system to pinpoint which buildings are consuming the most energy after hours, leading to a targeted initiative to install occupancy sensors for lighting controls.

Tech giant Microsoft successfully implemented an IWMS to consolidate facility data across more than 500 buildings. This move allowed them to standardize processes, gain unprecedented visibility into their global operations, and make strategic decisions based on comprehensive, real-time analytics.

Key Insight: The primary value of an IWMS is not just consolidation; it is the ability to correlate data from different functions. For instance, you can link rising energy costs (sustainability module) to a specific aging HVAC unit (maintenance module) in an underutilized area (space module) to justify a strategic replacement.

Implementing an IWMS: Actionable Steps

Deploying an IWMS requires careful planning to ensure a smooth transition and maximize return on investment.

- Define Clear KPIs: Before implementation, determine what success looks like. Key Performance Indicators could include a 15% reduction in maintenance work order response times or a 10% improvement in space utilization within the first year.

- Start with a Pilot Program: Roll out the system in a single building or department first. This allows you to identify and resolve potential issues, gather user feedback, and create a case study to build buy-in for a full-scale deployment.

- Prioritize Data Integrity: The system is only as good as the data it contains. Before migration, conduct a thorough audit of existing facility data. Standardize naming conventions, purge outdated information, and ensure accuracy to build a reliable foundation.

- Invest in Training: Comprehensive user training and change management are critical. Ensure all stakeholders, from technicians to executives, understand how to use the system and recognize its benefits for their specific roles.

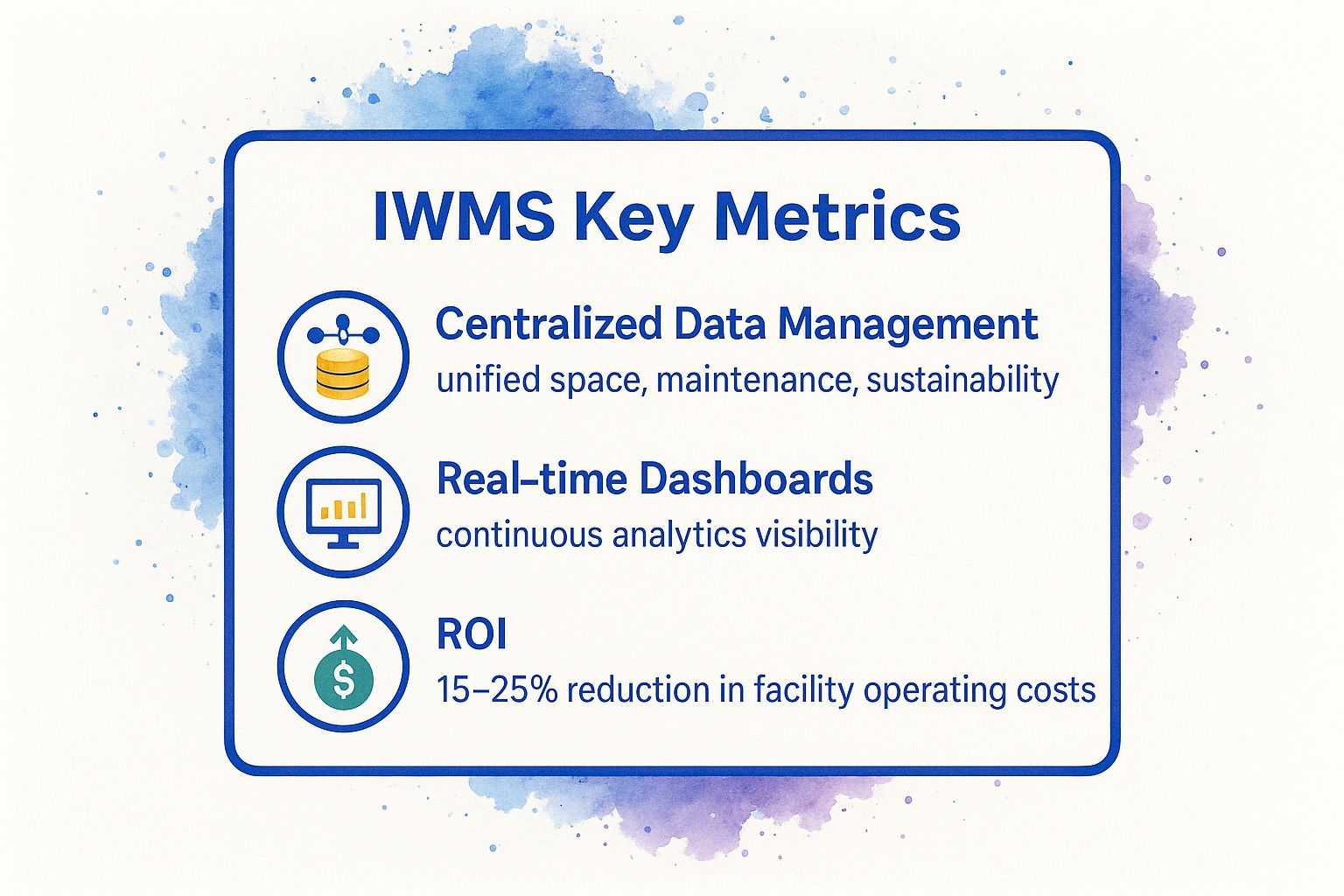

This infographic summarizes the core metrics that an IWMS helps facility managers track and improve.

As the visualization highlights, the core benefits of an IWMS revolve around centralized data, real-time visibility through dashboards, and a tangible reduction in operating costs. These outcomes are a direct result of replacing fragmented systems with a single, intelligent platform.

2. Preventive Maintenance Programs

Waiting for critical equipment to fail before taking action is a costly and disruptive approach to facility management. A Preventive Maintenance (PM) program shifts the paradigm from reactive repairs to proactive care. This systematic strategy involves scheduled inspections, servicing, and component replacements to address potential issues before they escalate into major failures, ensuring building systems operate at peak efficiency.

This proactive stance is a fundamental component of facility management best practices, as it directly reduces emergency downtime, extends the lifespan of expensive assets, and creates a safer, more reliable environment for occupants. By anticipating needs rather than reacting to crises, facility managers can control costs, improve budgeting accuracy, and maintain operational continuity.

How a PM Program Drives Efficiency

A robust PM program moves maintenance from an unpredictable expense to a planned operational activity. This strategic scheduling minimizes disruptions and ensures that crucial systems like HVAC, plumbing, and electrical are consistently reliable.

- Asset Longevity: Regular servicing, like lubricating bearings on a production line motor, prevents excessive wear and can extend its operational life by several years, delaying a major capital expenditure.

- Reduced Downtime: Scheduling a generator test during a weekend prevents the disruption of finding out it won't start during a weekday power outage, which could halt business operations for hours.

- Improved Safety: Proactively identifying and replacing a frayed electrical cord on a piece of machinery eliminates a significant fire and shock hazard, contributing to a safer workplace. A well-maintained facility also supports other safety measures, which can enhance workplace safety and comfort for everyone.

- Energy Savings: Regularly cleaning the coils on a commercial refrigeration unit ensures it doesn't have to work as hard to maintain temperature, directly reducing its electricity consumption. For those looking to optimize their operational expenses, exploring detailed commercial HVAC preventive maintenance strategies can offer significant cost savings.

Amazon's fulfillment centers, for example, leverage PM and predictive technologies to achieve an incredible 99.9% equipment uptime, ensuring that their complex conveyor and sorting systems run flawlessly to meet demanding delivery schedules. This demonstrates the immense value of a proactive maintenance culture.

Key Insight: The core benefit of a preventive maintenance program is transforming maintenance from an unpredictable liability into a strategic asset. By scheduling and controlling maintenance tasks, you gain direct control over operational costs, asset reliability, and overall facility performance.

Implementing a PM Program: Actionable Steps

Launching an effective PM program requires a methodical approach to ensure it delivers tangible results and is sustainable over the long term.

- Conduct a Full Asset Inventory: You can't maintain what you don't know you have. Create a comprehensive list of all critical equipment, including make, model, serial number, and installation date.

- Establish Maintenance Schedules: Use manufacturer recommendations as a baseline for creating initial PM schedules. Prioritize assets based on their criticality to business operations. For example, the main electrical switchgear should have a higher priority than a breakroom appliance.

- Develop Standardized Checklists: Create detailed checklists for each piece of equipment outlining specific tasks for technicians to perform during each service. For an air handling unit, this would include "Check belt tension," "Replace filters," and "Clean condensate pan." This ensures consistency and thoroughness.

- Leverage a CMMS: Use a Computerized Maintenance Management System (CMMS) to automate work order generation, track maintenance history, and analyze performance data to refine and optimize your PM schedules over time.

3. Space Utilization Optimization

In the modern workplace, real estate is often the second-largest expense after payroll. Simply having space is no longer enough; facilities must be designed and managed to maximize every square foot. Space utilization optimization is a data-driven approach that moves beyond traditional headcount-to-square-foot ratios, focusing instead on how physical space is actually used. This practice involves measuring occupancy patterns, analyzing usage data, and reconfiguring layouts to align the workspace with organizational needs and employee work styles.

By shifting from assumptions to empirical data, facility managers can make informed decisions that reduce real estate costs, boost employee productivity, and enhance workplace satisfaction. This analytical approach is a cornerstone of facility management best practices because it ensures that the physical environment is an asset that actively supports business objectives, rather than a passive, costly overhead.

How Data-Driven Space Planning Drives Efficiency

Optimizing space utilization requires a detailed understanding of how, when, and where work happens. This is achieved by gathering and analyzing data from various sources to create a complete picture of workplace dynamics.

- Occupancy Analysis: A tech company uses Wi-Fi connection data to discover that its large, 12-person conference rooms are used by only 2-3 people 80% of the time. This data justifies a project to convert two large rooms into six smaller "huddle rooms," better meeting employee needs.

- Activity-Based Working (ABW): Instead of assigning every employee a desk, a marketing agency designs its office with a mix of collaborative tables, quiet "library" zones, and private phone booths. Employees choose the space that best fits their task for the day, boosting both focus and teamwork.

- Space Consolidation: A law firm analyzes badge-swipe data and finds that due to a new hybrid work policy, two of its five floors are consistently below 25% occupancy. They consolidate their operations onto three floors and sublet the other two, immediately cutting lease and utility costs by 40%.

- Improved Employee Experience: By using a room-booking system, employees can see which meeting rooms are available in real-time on their phones. This eliminates the frustration and wasted time of walking around searching for an open space, a direct benefit to their daily workflow.

Global real estate firm CBRE implemented activity-based working across its own offices after utilization data revealed that desks were empty 55% of the time. This data-backed strategy led to a 30% reduction in their required office space while simultaneously increasing employee satisfaction and collaboration.

Key Insight: True optimization isn't just about shrinking the footprint. It's about reallocating resources to high-value spaces. Data might show a constant shortage of small, two-person meeting rooms while a large boardroom sits empty. The strategic response is to subdivide the boardroom, directly addressing an identified employee need and improving workflow efficiency.

Implementing Space Utilization Optimization: Actionable Steps

A successful optimization project requires a structured, people-first approach to ensure changes are adopted and goals are met.

- Establish a Baseline: Before making any changes, collect at least three to six months of utilization data. This baseline is crucial for measuring the impact of your initiatives and demonstrating ROI. Use a mix of technology (like Density.io sensors) and qualitative methods (employee surveys).

- Involve Employees in the Process: Share the "why" behind the project and gather feedback through workshops and surveys. When employees understand the benefits and have a voice in the design, they are far more likely to embrace new ways of working.

- Launch a Pilot Program: Test new space concepts in a specific department or on a single floor. This allows you to gather real-world feedback, resolve unforeseen issues, and build a success story that encourages wider adoption.

- Continuously Monitor and Adapt: The modern workplace is dynamic. Regularly review utilization data and employee feedback to make ongoing adjustments. Space optimization is not a one-time project but a continuous cycle of measurement, analysis, and refinement.

4. Energy Management and Sustainability

Beyond simply keeping the lights on, modern facility management is deeply intertwined with environmental stewardship and fiscal responsibility. A strategic approach to energy management and sustainability focuses on minimizing a building's environmental impact and reducing utility expenses through efficient technologies, optimized operations, and sustainable practices. This moves energy from a fixed cost to a manageable variable, directly impacting the bottom line.

This focus is a critical component of facility management best practices because it addresses two major organizational goals simultaneously: reducing operational costs and enhancing corporate social responsibility. By systematically tracking and managing energy consumption, facility managers can uncover significant savings, improve building performance, and contribute to a healthier planet.

How Sustainability Drives Efficiency

A comprehensive energy management program integrates technology, processes, and people to create a culture of conservation and efficiency. This holistic approach ensures that energy-saving efforts are sustainable and continuously improving.

- Building Automation Systems (BAS): A BAS in a commercial office building can automatically dim lights near windows on a sunny day and reduce HVAC output during unoccupied hours, saving energy without any manual intervention.

- Energy-Efficient Upgrades: A manufacturing plant replaces its old, high-pressure sodium lighting with modern LEDs. This single upgrade reduces lighting-related energy costs by 70% and improves visibility and safety on the factory floor.

- Renewable Energy Integration: A large distribution center installs solar panels on its expansive, flat roof. This generates enough clean electricity to power its operations during peak daylight hours, drastically reducing its reliance on the grid and saving thousands in utility bills.

- Waste and Water Reduction: A hotel implements a linen reuse program and installs low-flow showerheads and toilets. These measures significantly cut water consumption and sewer costs, while also appealing to environmentally conscious guests.

The iconic Empire State Building's deep energy retrofit project is a prime example. The project achieved a 38% reduction in energy use, saving an estimated $4.4 million annually and proving that even historic structures can become models of efficiency.

Key Insight: True sustainability is not about isolated initiatives but about creating a closed-loop system. For instance, data from your BAS (automation) can pinpoint inefficient equipment, justifying a capital request for an energy-efficient upgrade (technology), which is then promoted through an employee awareness campaign (people) to maximize savings.

Implementing an Energy Management Program: Actionable Steps

Launching a successful sustainability program requires a clear strategy and a phased approach to ensure long-term success and buy-in from all levels of the organization.

- Conduct a Comprehensive Energy Audit: You cannot manage what you do not measure. Start by hiring a professional or using an in-house team to perform a detailed audit to benchmark current consumption and identify the most significant opportunities for improvement.

- Target Low-Hanging Fruit First: Implement no-cost or low-cost measures to generate quick wins. This includes adjusting thermostat setpoints by a few degrees, sealing air leaks around windows and doors, and educating staff to turn off equipment at the end of the day. Maximizing cost savings and environmental responsibility requires implementing practical energy efficiency tips that can make an immediate impact.

- Invest in Monitoring Technology: Deploy energy management software or sub-metering systems to gain real-time visibility into consumption patterns. This allows for continuous monitoring, anomaly detection, and verification of savings from implemented projects.

- Engage and Educate Occupants: Your building’s occupants are key partners in any sustainability initiative. Create awareness campaigns, provide regular updates on progress, and consider incentive programs to encourage energy-conscious behaviors. By fostering a shared sense of purpose, you can significantly amplify your program's results. For more details on this topic, you can learn more about business sustainability initiatives.

5. Vendor and Contractor Management

The performance of a facility is often a direct reflection of the external partners hired to maintain it. From custodial services to HVAC technicians and security firms, vendors and contractors are essential extensions of the in-house team. A strategic approach to vendor and contractor management moves beyond simple procurement to a comprehensive lifecycle of selection, oversight, and partnership optimization. This practice ensures every external provider meets quality standards, complies with regulations, and delivers maximum value.

Effective vendor management is a crucial component of facility management best practices because it directly impacts operational costs, risk exposure, and service quality. By formalizing processes, setting clear expectations, and actively managing these relationships, facility managers can prevent service disruptions, control budgets, and ensure that specialized tasks are handled by qualified experts, freeing up internal teams to focus on core business objectives.

How Strategic Vendor Management Drives Value

A structured vendor management program creates a framework for accountability and continuous improvement. It transforms transactional relationships into strategic partnerships that align with the organization's goals.

- Service Level Agreements (SLAs): An SLA for a landscaping contractor might specify that lawns must be mowed weekly between April and October, all clippings must be removed, and any irrigation issues must be reported within 4 hours. This leaves no room for ambiguity.

- Contract & Compliance Management: A facility manager uses software to track that their fire suppression system vendor has up-to-date insurance and technician certifications, preventing a major compliance issue during a city inspection.

- Performance Tracking: A manager uses a simple rating system after each service call to track a plumbing contractor's response time, professionalism, and first-time fix rate. This data provides objective evidence for contract renewal discussions.

- Cost Optimization: A property management company that oversees ten buildings consolidates its janitorial services with a single, high-performing vendor instead of ten different ones. This allows them to negotiate a 15% bulk discount while ensuring consistent cleaning standards across all properties.

Amazon's global operations rely on a sophisticated vendor management system to onboard, manage, and pay thousands of facility service providers. This centralized approach allows them to maintain consistent standards for everything from routine maintenance to specialized equipment repairs across a massive, diverse portfolio of properties.

Key Insight: The goal is not just to find the cheapest provider, but the one that offers the best long-term value. A slightly more expensive contractor who is reliable, communicates effectively, and proactively identifies issues can save you significantly more in emergency repair costs and downtime than a low-bid provider who cuts corners.

Implementing a Vendor Management Program: Actionable Steps

Building an effective vendor management program requires a clear strategy and consistent execution.

- Develop a Standardized Vetting Process: Create a checklist for evaluating all potential vendors. This should include checks for licenses, insurance, references, and safety records to ensure only qualified and reliable partners are considered.

- Establish Clear Communication Channels: Implement a system for all vendor communications, work orders, and invoicing. Using a dedicated software platform or portal can prevent miscommunications and create a clear audit trail. This is essential whether you're coordinating a one-time installation or managing ongoing services like the replacement of high-traffic entrance floor mats.

- Conduct Regular Performance Reviews: Schedule quarterly or bi-annual meetings with key vendors to review performance against SLAs. Use this time to discuss challenges, provide feedback, and align on future goals.

- Maintain a Backup Vendor List: For critical services like plumbing, electrical, or security, identify and pre-qualify backup vendors. This ensures that a single point of failure won't cripple your facility's operations during an emergency.

6. Emergency Preparedness and Business Continuity

In today's unpredictable environment, waiting for a crisis to happen is a strategy for failure. Emergency preparedness and business continuity planning is a proactive framework that ensures an organization can protect its people, property, and operations during a disruptive event. This goes beyond simply having a fire drill; it involves a comprehensive strategy for resilience against everything from natural disasters and equipment failures to security threats and public health crises.

This systematic preparation is a critical component of modern facility management best practices, shifting the focus from reactive damage control to proactive resilience. By anticipating potential disruptions and creating clear, actionable protocols, facility managers ensure operational stability, safeguard assets, and maintain a safe environment for employees and visitors, no matter the circumstances.

How Preparedness Ensures Resilience

A robust emergency and business continuity plan integrates risk assessment, response protocols, and recovery strategies into a single, cohesive framework. This ensures that every team member knows their role and can act decisively when a crisis occurs.

- Risk Assessment: A facility located in a flood-prone area identifies this as a high-priority risk. Their plan includes pre-positioned sandbags, procedures for moving critical equipment to higher floors, and a contract with a water damage restoration company.

- Response Protocols: An office develops a clear "shelter-in-place" protocol for severe weather. The plan designates the safest interior rooms, includes an emergency supply kit in each, and uses a mass notification system to alert all employees simultaneously.

- Asset Protection: Before a hurricane, a manufacturing plant follows a checklist to secure loose outdoor equipment, board up windows, and perform a final data backup to an off-site server, minimizing potential damage and data loss. A crucial aspect of business continuity involves protecting your physical and digital assets. Understanding how to approach choosing security labels to protect assets can be a key component of your overall security strategy.

- Business Continuity: After a fire damages its primary office, a financial services firm executes its continuity plan. Key employees work from a pre-arranged alternate location while the rest work from home, using cloud-based systems to continue serving clients with minimal interruption.

A prime example is Walt Disney World's emergency management, which successfully navigated Hurricane Ian. By executing a well-rehearsed plan, they secured park assets, communicated effectively with guests, and resumed operations swiftly and safely, minimizing both financial loss and reputational damage.

Key Insight: Emergency preparedness is not a one-time project but a continuous cycle. The plan must be a living document, regularly reviewed and updated to reflect new risks, changing business operations, and lessons learned from drills and real-world events.

Implementing a Business Continuity Plan: Actionable Steps

Creating an effective plan requires a structured approach that involves stakeholders from across the organization.

- Conduct a Business Impact Analysis (BIA): Identify your organization's most critical business functions and the resources they depend on. This analysis will help you prioritize recovery efforts and allocate resources effectively.

- Establish Clear Communication Channels: Design a multi-layered communication plan that includes primary and backup systems like mass notification software, a dedicated hotline, and social media updates. Ensure all employee and key stakeholder contact information is current.

- Practice Through Drills and Simulations: Regularly conduct drills, from tabletop exercises discussing a hypothetical scenario to full-scale simulations involving evacuations. These practices build "muscle memory" and reveal weaknesses in your plan before a real crisis hits.

- Coordinate with External Partners: Build relationships with local emergency services, such as fire and police departments, and coordinate your plans with them. Also, identify backup suppliers and vendors to ensure your supply chain remains intact during a disruption.

7. Data-Driven Decision Making

In today's competitive landscape, managing facilities based on intuition or historical precedent is no longer enough. Data-driven decision making is the practice of systematically collecting, analyzing, and applying facility performance data to make informed choices about space, maintenance, energy use, and overall operations. This approach leverages technologies like IoT sensors and advanced analytics to shift management from reactive problem-solving to a predictive and strategic model.

By grounding choices in objective data, facility managers can optimize resource allocation, anticipate maintenance needs before they become critical failures, and create more efficient, cost-effective environments. This is a crucial element of modern facility management best practices because it provides irrefutable evidence to justify investments, prove ROI, and drive continuous improvement across the organization.

How Data Drives Efficiency

A data-driven approach integrates information from various sources to create a holistic view of facility performance. This allows managers to identify patterns and correlations that would otherwise go unnoticed, leading to significant operational enhancements.

- Predictive Maintenance: IoT vibration sensors on a critical manufacturing machine detect a minor, unusual pattern. The system flags this anomaly, allowing technicians to replace a wearing bearing during planned downtime, preventing a catastrophic failure that would have halted production for a full day.

- Space Optimization: An analysis of meeting room booking data shows that 90% of bookings are for four people or fewer. This data justifies the decision to convert an underused large conference room into three smaller huddle rooms, directly addressing a clear demand and improving space efficiency.

- Energy Management: A smart building system correlates occupancy data with HVAC usage, revealing that an entire wing of a building is being heated and cooled on weekends when it is empty. A simple scheduling adjustment based on this data leads to a 15% reduction in weekend energy consumption.

- Enhanced Occupant Experience: A facility manager uses data from indoor air quality sensors to show a correlation between high CO2 levels in the afternoon and a drop in employee-reported productivity. This data justifies an investment to improve ventilation, directly impacting occupant well-being and performance. Analyzing how people move through a space can also inform decisions on everything from cleaning schedules to the placement of ergonomic matting, which is vital for understanding ergonomics in the workplace.

Salesforce famously uses IoT data from its global offices to optimize HVAC systems, resulting in an estimated 30% reduction in energy costs. This demonstrates how leveraging real-time data can produce substantial financial and environmental benefits.

Key Insight: The true power of data is in its ability to connect operational activities to business outcomes. For example, you can correlate a rise in employee complaints about thermal comfort (occupant feedback) with specific HVAC performance data (sensor readings) to justify a targeted system upgrade that directly improves productivity.

Implementing a Data-Driven Strategy: Actionable Steps

Transitioning to a data-centric model requires a clear strategy to ensure the insights generated are both accurate and actionable.

- Start with Key Business Questions: Instead of collecting data for its own sake, define the problems you need to solve. Are you trying to reduce energy costs, improve space utilization, or decrease equipment downtime? Your goals will determine what data you need to collect.

- Invest in Data Literacy: Your team is your greatest asset. Provide training on data analysis, interpretation, and the use of visualization tools like Tableau or Power BI. This empowers staff at all levels to understand and act on the insights generated.

- Ensure Data Quality and Integrity: Inaccurate data leads to poor decisions. Implement a regular maintenance schedule for sensors and meters to ensure they are properly calibrated. Establish clear protocols for data entry and management to maintain a reliable dataset.

- Establish Data Governance: Create clear policies regarding data privacy, security, and access. This is essential for protecting sensitive information and ensuring compliance with regulations like GDPR, building trust among employees and stakeholders.

Facility Management Best Practices Comparison

| Item | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

| Integrated Workplace Management Systems (IWMS) | High (6-18 months, complex integration) | Significant: IT infrastructure, training, change management | 15-25% facility cost reduction, improved analytics, compliance | Large organizations needing centralized facility data and portfolio management | Eliminates data silos, real-time insights, scalable |

| Preventive Maintenance Programs | Moderate (planning and training needed) | Skilled maintenance staff, IoT sensors, scheduling tools | Up to 50% emergency cost reduction, extended equipment life | Facilities aiming to reduce downtime and repair costs | Reduces emergencies, extends asset lifespan, compliance support |

| Space Utilization Optimization | Moderate to High (sensor tech and analytics) | Investment in sensors, analytics platforms, change management | 15-30% real estate cost savings, improved employee satisfaction | Organizations optimizing workspace for hybrid or flexible work models | Data-driven space planning, supports flexibility and sustainability |

| Energy Management and Sustainability | High (capital intensive, specialized expertise) | Capital investment in energy-efficient tech, ongoing monitoring | 20-40% energy cost reduction, improved ESG ratings | Facilities targeting energy efficiency and sustainability goals | Cost savings, tax incentives, enhanced property value |

| Vendor and Contractor Management | Moderate (process and relationship management) | Staff for vendor oversight, management platforms | Cost savings through bidding, improved service quality | Organizations managing multiple external service providers | Cost control, quality improvement, risk mitigation |

| Emergency Preparedness and Business Continuity | Moderate to High (planning, training, coordination) | Investment in planning, training, communication systems | Enhanced safety, reduced downtime and liability | Organizations requiring risk mitigation and resilience | Protects people and assets, ensures compliance, reduces recovery time |

| Data-Driven Decision Making | High (technology and skill demands) | IoT sensors, analytics software, skilled analysts | Improved operational efficiency, informed decision-making | Facilities transitioning to predictive and strategic management | Proactive optimization, objective insights, compliance support |

Putting These Practices Into Action Today

Moving from understanding to implementation is the most critical step in revolutionizing your facility management approach. The seven best practices we've detailed, from leveraging an Integrated Workplace Management System (IWMS) to fostering a culture of data-driven decision-making, are not standalone tactics. Instead, they are deeply interconnected components that form a powerful, holistic system for operational excellence.

The sheer volume of potential improvements can feel overwhelming, but progress begins with a single, targeted action. You don't need to overhaul your entire operation overnight. The key is to start strategically.

Your First Actionable Steps

Identify the one or two areas from this guide that represent your facility's most significant pain points or offer the greatest opportunity for immediate impact.

- Is equipment downtime a constant headache? Your first step is to formalize your preventive maintenance program. Start by inventorying your critical assets and creating a simple, calendar-based schedule for inspections and servicing.

- Are you facing complaints about a lack of meeting rooms or quiet workspaces? Begin with a basic space utilization audit. For one week, have staff manually track how key areas are used to gather initial data on peak times and underused zones.

- Do you feel like you're flying blind without concrete data? Focus on implementing one or two key performance indicators (KPIs). Start tracking something simple but impactful, like the number of work orders completed on time or monthly energy consumption.

Small, consistent actions in these areas will build momentum, leading to more significant, facility-wide transformations. As you implement these high-level strategies, never lose sight of the foundational elements that ensure a safe, clean, and welcoming environment for everyone.

The Foundation of Excellence: Safety and Cleanliness

Mastering facility management best practices is impossible without a solid foundation. Proactive safety measures and stringent cleanliness protocols are not just line items on a checklist; they are prerequisites for a high-functioning building. This is where strategic, on-the-ground solutions become indispensable.

For example, a robust preventive maintenance plan reduces the risk of equipment failure, a key safety concern. Similarly, optimizing your space can prevent overcrowding and improve emergency egress routes. Every best practice we've discussed ultimately contributes to a safer, more efficient, and cleaner environment.

This foundational layer is often most vulnerable at your building's entry points, where dirt, moisture, and debris are tracked inside, creating slip hazards and increasing the cleaning workload for your team.

Key Insight: A well-managed facility integrates high-level strategic planning with essential, practical solutions. Neglecting the basics, like entryway safety and cleanliness, will undermine even the most advanced management systems.

By thoughtfully combining the strategic practices outlined in this guide with essential, high-quality facility solutions, you create a powerful synergy. You transition from a reactive management style to a proactive, forward-thinking approach. The result is a facility that is not merely maintained but is a genuine asset, actively contributing to your organization's productivity, safety, and overall success. This comprehensive approach is the true hallmark of effective facility management.

Elevate your facility's safety and cleanliness from the ground up. The right matting is a critical component of any effective facility management strategy, trapping dirt at the door and preventing slip-and-fall incidents. Explore our comprehensive range of high-performance entrance, safety, and anti-fatigue mats at Mats4U to build a stronger foundation for your operational excellence.