Anti-fatigue industrial mats are a crucial tool for any workplace where employees spend their day on their feet. At their core, they're specially designed surfaces that fight back against the physical strain and sheer discomfort of prolonged standing.

They work by encouraging tiny, continuous muscle movements in your legs and feet. This micro-movement is key to keeping blood flowing properly, which dramatically cuts down on the fatigue that builds up in the legs, back, and feet. This guide will show you how to choose the right mats to transform them from a simple "nice to have" into a strategic investment for your industrial workplace.

The Hidden Costs of Standing All Day

Picture a worker on your assembly line. It’s 2 PM. Their focus is starting to drift as a dull ache in their legs and back quietly takes hold. This isn't just about comfort—it's a massive operational bottleneck that chips away at your bottom line through lost efficiency and higher safety risks.

Standing for hours on hard concrete is surprisingly brutal on the human body. Muscles become static and constricted, which clamps down on blood flow and lets pain build up, especially in the lower back, legs, and feet. This physical toll has very real consequences for the business.

Understanding the Impact on Your Business

The negative effects of worker fatigue don't stay hidden for long; they quickly show up as measurable losses. As discomfort grows, employees are far more likely to take unscheduled breaks, make costly errors, or simply work at a slower pace.

Here’s how these hidden costs manifest in your operations:

- Reduced Productivity: Fatigued workers are less focused and less efficient. This leads directly to lower output per shift and missed production targets. For example, a packing station might see its items-per-hour rate drop by 15-20% in the last two hours of a shift as physical discomfort sets in.

- Increased Safety Risks: Aches and pains are a huge distraction. A split second of lost concentration can lead to an accident, and tired legs make slips, trips, and falls much more likely. A distracted machine operator is a significant liability.

- Higher Absenteeism: Chronic pain from poor ergonomics is a top reason for employees calling in sick, which throws a wrench in the workflow and piles extra work onto the remaining staff. This can lead to overtime costs and production delays.

The Science Behind the Solution

This is where anti fatigue industrial mats become a strategic part of your toolkit. Think of them like the suspension system in a car. Just as a car's suspension absorbs the jarring impact of a bumpy road, these mats absorb the shock of standing on a hard, unforgiving surface.

An effective anti-fatigue mat is designed to be just unstable enough to force small, continuous muscle movements in the legs and feet. This "muscle-pump" action is crucial for promoting healthy blood circulation and preventing the static muscle load that causes pain.

This constant, subtle motion keeps blood from pooling in the legs, which gets more oxygen to the muscles and significantly pushes back the onset of fatigue.

The growing awareness of these benefits is plain to see. The industrial anti-fatigue floor mat market was valued at USD 1.52 billion in 2024 and is projected to hit USD 2.78 billion by 2033, which shows just how many businesses are now investing in their employees' well-being. By reframing this purchase from a simple amenity to a core operational investment, you can directly tackle these hidden costs.

To see how this works in practice, check out our guide on the top 7 anti-fatigue mat benefits for your workplace.

How Anti-Fatigue Mats Improve Your Bottom Line

It can sometimes feel like a stretch to connect employee comfort directly to your company's financial health. But when it comes to anti-fatigue industrial mats, the return on investment isn't just an abstract idea—it’s clear, measurable, and impacts the areas that matter most. We're moving beyond simple comfort here. These mats deliver real value by boosting safety, driving productivity, and helping you keep your best people.

Putting money into workplace ergonomics isn't just some passing trend; it's a core business strategy that's gaining serious momentum. The global market for anti-fatigue mats was already valued at USD 1.87 billion in 2024 and is on track to hit USD 3.14 billion by 2034. This explosive growth shows a widespread understanding of the direct financial upside of looking after your team's well-being.

Reduce Costly Safety Incidents

Slips, trips, and falls are some of the most common—and most expensive—accidents that can happen on the job. Day after day, standing on hard, unforgiving floors doesn't just create these immediate dangers; it also leads to long-term musculoskeletal problems that result in costly workers' compensation claims.

How to Take Action:

- Install runners with beveled edges in high-traffic walkways to prevent tripping.

- Use mats with textured surfaces in areas prone to moisture or spills.

- Benefit: A safer floor directly reduces accident-related costs, from insurance premiums to lost workdays.

Real-World Example: A busy warehouse distribution center was dealing with a high number of back and knee injury claims. They installed anti-fatigue runners along their main packing and sorting lines. The result? They saw a 40% reduction in musculoskeletal-related incident reports in the first year alone, saving them tens of thousands in insurance and compensation costs.

Drive Measurable Productivity Gains

Discomfort is a massive distraction. When your team members are constantly shifting their weight, trying to get comfortable on a hard floor, their focus is split and their efficiency drops. It's a simple equation: a comfortable worker is a productive worker.

By providing a supportive surface, anti-fatigue mats let employees concentrate fully on their work instead of their aching feet. This sustained focus means fewer errors, faster work cycles, and higher output every single shift.

How to Take Action:

- Place individual mats at fixed workstations where employees stand for long periods.

- Monitor key performance indicators (KPIs) like units per hour or error rates before and after installation.

- Benefit: You gain tangible improvements in operational efficiency and product quality.

Real-World Example: An automotive parts assembly line where workers are on their feet for eight-hour shifts doing detailed, precise tasks. After bringing in high-quality anti-fatigue industrial mats, the facility manager recorded a 12% increase in units assembled per hour. They also saw a major drop in products rejected by quality control due to assembly errors.

Improve Employee Retention and Morale

High turnover is incredibly expensive. The costs of recruiting, hiring, and training new staff add up fast. In physically demanding jobs, investing in ergonomics is a powerful tool for keeping your team happy and stable. It sends a loud, clear message: you value your people and their health. To see just how deep this connection goes, you can learn more about how anti-fatigue mats and your health are linked.

When employees feel looked after, morale gets a boost, absenteeism goes down, and they’re far more likely to stick around for the long haul. This one simple investment can be the difference between a revolving door of new hires and a stable, experienced, and loyal workforce.

Selecting the Right Mat Material for Your Workspace

Choosing the wrong material for your anti-fatigue industrial mats is a lot like using the wrong tool for a critical job—it’s an expensive mistake that tanks both safety and performance. The material isn't just some minor detail; it's the very core of the mat's ability to stand up to your specific workplace challenges. A mat that’s perfect for a dry packing station will fail spectacularly when exposed to oils and chemicals.

This guide is all about giving you practical advice to match the right material to your real-world industrial needs. Getting this right from the start means you invest in a durable, effective solution, not a recurring replacement cost.

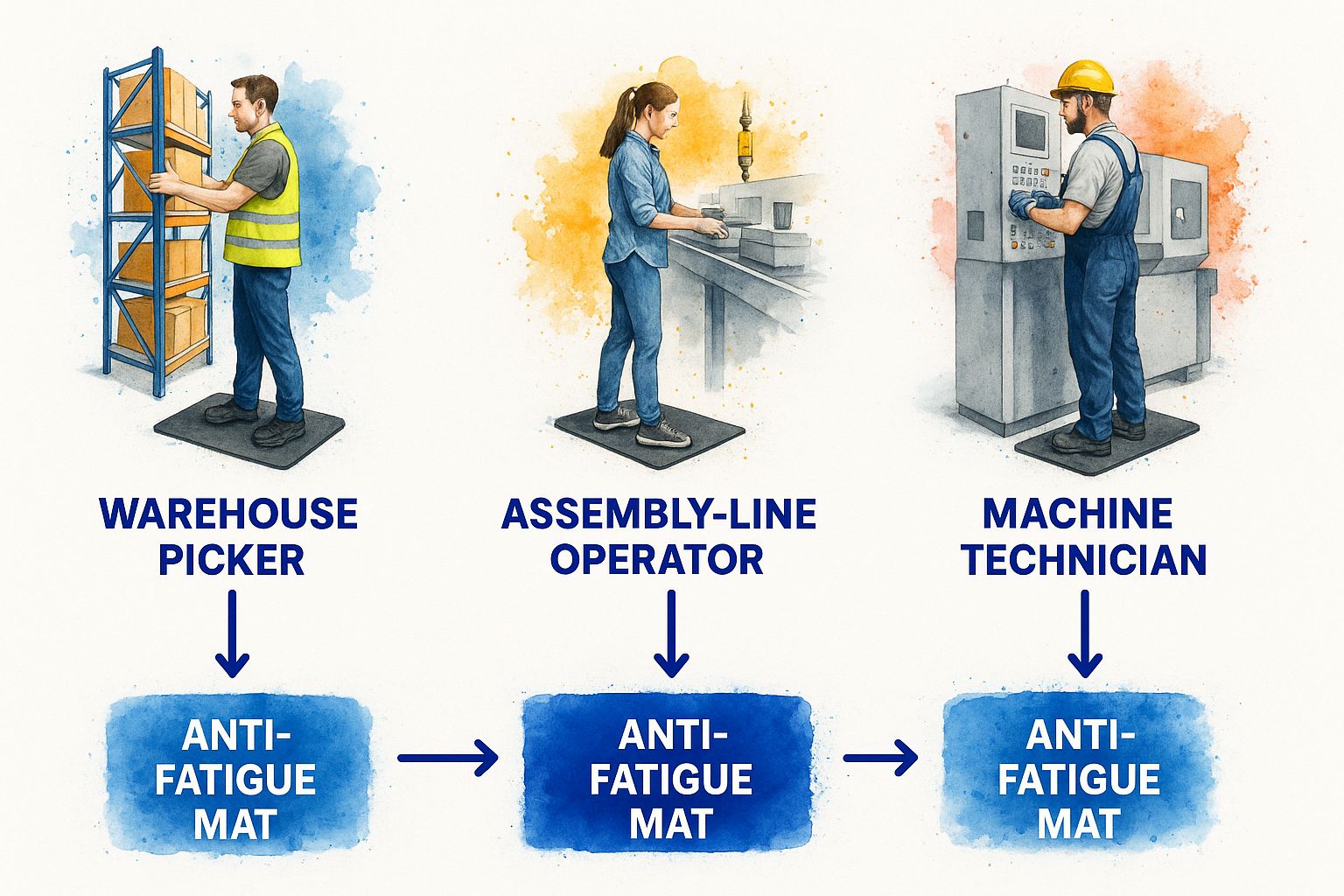

This visual breakdown helps show which mat is best suited for different industrial roles, from a warehouse picker to a machine operator.

As you can see, the secret is aligning the mat’s properties with the specific hazards and demands of the job at hand.

Nitrile Rubber for Harsh Environments

When your workspace is dealing with oils, greases, or harsh chemicals, nitrile rubber is the only real choice. Think of it as heavy-duty armor for your floors. Nitrile is specifically engineered to resist breaking down when exposed to the petroleum-based fluids that would cause other materials to swell up, curl at the edges, and fall apart.

Real-World Example: A CNC machine shop is the perfect scenario. Coolants, lubricants, and metal shavings are part of the daily routine. A standard mat would become a saturated, slippery hazard in a matter of weeks. A nitrile rubber mat, however, holds its ground, maintaining its structure and slip resistance to provide a safe, stable platform for technicians. This choice directly reduces slip-and-fall risks and extends the mat's lifespan, saving on replacement costs.

PVC (Vinyl) for Dry and General-Purpose Areas

For those dry work areas that are free from aggressive chemicals, PVC (Polyvinyl Chloride)—often just called vinyl—is an excellent and budget-friendly option. It provides solid ergonomic support for workers in places like electronics assembly, packing stations, or busy fulfillment centers.

A key benefit of PVC is its sheer versatility and affordability, especially for large-scale deployments. It's the go-to material for covering long assembly lines or individual workstations where the main goal is simply ergonomic relief from standing on hard concrete all day.

Real-World Example: A large e-commerce fulfillment center needs to cover hundreds of feet of packing lines. Using cost-effective PVC anti-fatigue runners provides immediate comfort for a large number of employees, boosting morale and stamina during long shifts without the higher cost of specialized rubber.

Understanding the Trade-Offs

The best choice always comes down to your specific application. A mat's material directly dictates how effective it will be and how long it will last. To help you zero in on the right one, let’s break down the main contenders.

Industrial Mat Material Comparison Guide

This table offers a quick, side-by-side look at the most common anti-fatigue mat materials. Use it to select the best option based on your facility's unique environment and challenges.

| Material Type | Best For (Environment) | Key Advantage | Potential Drawback |

|---|---|---|---|

| Nitrile Rubber | Oily, greasy, and chemical-heavy areas like machine shops or industrial kitchens. | Exceptional Durability: Resists oils, chemicals, and extreme temperatures, ensuring a long service life. | Higher initial investment compared to other materials. |

| PVC (Vinyl) | Dry assembly lines, packing stations, and general-purpose industrial settings. | Cost-Effective Comfort: Provides excellent ergonomic support at an affordable price point. | Prone to cracking and curling if exposed to oils or harsh chemicals. |

Making an informed decision on the material is absolutely critical to the mat's performance. It’s worth understanding how long anti-fatigue mats last under different conditions, as picking the right material from the start will maximize your investment. By matching the mat to its environment, you lock in safety, comfort, and durability for the long haul.

What to Look For: Essential Features of a Top-Tier Industrial Mat

Once you've settled on the right material, the real magic is in the details. Specific design features are what elevate a mat from just "good enough" to a genuine safety asset. Think of this as your pre-flight checklist for spotting the critical performance and safety details that every anti fatigue industrial mat needs to have. Getting these right means your investment is actively working to prevent accidents, not just aches and pains.

The Non-Negotiable Safety Feature: Beveled Edges

Let's be clear: beveled edges are not optional. They are a fundamental safety requirement. These are the sloped or tapered borders that create a smooth, ramp-like transition from the floor up to the mat’s surface. This simple design trick is a game-changer for preventing the slips and trips that make up a huge number of workplace injuries.

Real-World Example: Picture a busy warehouse corridor where workers are constantly pushing heavy carts. A hard, 90-degree edge can easily snag a cart wheel, bringing it to a dead stop or even tipping it over. With beveled edges, that same cart glides up and onto the mat without a hitch, keeping the workflow smooth and eliminating a dangerous catch point. This feature directly supports operational flow and prevents accidents.

A beveled edge is all about minimizing the mat's profile so it doesn't become an obstacle. For any mat in a high-traffic zone, this isn't a luxury add-on; it's the baseline for safety.

Getting a Grip: Surface Texture and Drainage

The surface of the mat is your first line of defense against slips, particularly when liquids get involved. A perfectly smooth surface might look clean, but it can become dangerously slick in wet or oily conditions. That’s why an aggressive surface texture or a raised pattern is essential for providing solid grip.

For spots that see a lot of fluid, drainage becomes just as important. Mats designed with built-in drainage holes are brilliant for two reasons:

- Keeps Feet Drier: They allow liquids—water, oils, coolants—to pass straight through. This keeps the top surface much drier and safer to stand on.

- Manages Debris: In a machine shop, small bits of debris like metal shavings can fall through the holes. This keeps the standing surface clear and cuts down on another potential slip hazard.

Real-World Example: In a food processing plant where floors are frequently hosed down, a mat with drainage holes and an aggressive texture is non-negotiable. It allows water to flow away, preventing pooling, while ensuring workers maintain secure footing even on wet surfaces. This is a direct investment in preventing slips and falls.

Special Ops: Advanced Features for Sensitive Environments

Some industries have unique challenges that require mats with highly specialized properties to protect products, equipment, or sterile conditions.

- ESD (Electrostatic Dissipative) Properties: If you work in electronics manufacturing or a server room, these mats are an absolute must. They safely ground the static electricity that builds up on a worker, protecting sensitive components from getting fried. For example, a technician building circuit boards could cause thousands of dollars in damage with a single static discharge; an ESD mat neutralizes this threat.

- Antimicrobial Surfaces: In cleanrooms, pharmaceutical labs, and healthcare facilities, hygiene is everything. Mats with antimicrobial properties are designed to inhibit the growth of bacteria and fungi, helping to maintain a sterile environment and support strict cleaning protocols.

By looking for these specific features, you can move past buying a generic mat and start specifying the exact tool your facility needs. For a more complete picture, check out our deep dive into industrial anti-fatigue mats for more insights.

Proper Sizing and Installation to Maximize Safety

Even the best anti fatigue industrial mat money can buy can turn into a serious liability if it’s the wrong size or slapped down carelessly. An undersized mat is a classic mistake. It forces workers to constantly step on and off the edge, which not only defeats the purpose but also creates a brand-new trip hazard.

Getting the sizing and installation right isn't just a finishing touch; it’s a critical step that turns your purchase into a genuine safety solution. It all starts with watching how your team actually works. The mat needs to be big enough to cover their entire range of motion, so they aren't forced to step off it just to do their job.

How to Correctly Measure a Workstation: An Actionable Plan

To get the coverage you need, you have to measure for the human element, not just the machine. Follow this simple process to get it right the first time.

- Define the Work Zone: Watch an employee during a typical shift. Notice how they move from side to side and back and forth. This entire area is their active work zone.

- Measure and Add a Buffer: Measure the length and width of that active space. Now, add a safety buffer of at least 6-12 inches (15-30 cm) on all sides. This extra room ensures that even when they reach, pivot, or turn, their feet stay planted firmly on the mat.

- Consider Equipment: Don't forget about carts, toolboxes, or any mobile equipment that rolls into the area. The mat can't get in the way or create a bumpy, uneven surface for wheels.

Individual Mats vs. Modular Systems: Making the Right Choice

The layout of your floor will point you toward the right matting format. For simple, isolated workstations, a single, standalone mat is often all you need.

Real-World Example: A technician at a standalone CNC machine does all their work in one contained spot. A single, perfectly sized anti fatigue industrial mat provides targeted support and is easy to clean or replace. This simple choice is both effective and efficient.

But for long assembly lines or awkwardly shaped work areas, modular, interlocking tiles are a much smarter solution.

Real-World Example: An automotive assembly line stretches over 100 feet. Instead of lining up dozens of individual mats (creating trip hazards at every seam), the facility uses an interlocking tile system. This creates a continuous, seamless surface of any length, eliminating gaps and providing consistent support for every worker along the line.

Finally, the installation itself is the last critical step. Always start with a completely clean, dry floor. This prevents nasty mold growth and helps the mat lay perfectly flat. Once you've got it in position, do a final check to make sure every edge, especially the beveled ones, sits flush with the floor. A single curled corner can quickly become a stubborn and dangerous trip hazard for everyone.

Simple Maintenance to Protect Your Investment

Think of your anti fatigue industrial mats as another piece of critical equipment, not just some disposable flooring you can forget about. Just like any other tool in your facility, they need regular care to do their job right and last as long as they should. A simple maintenance plan is all it takes to protect your investment and keep your team safe.

Proper care really isn't complicated, but it's what stops small issues from turning into major liabilities. By building a few quick checks into your facility’s daily routine, you can get a lot more life out of your mats and ensure they keep delivering those crucial ergonomic benefits.

Your Actionable Mat Care Plan

Consistency is everything. You don't need some complex, bureaucratic system; a simple, repeatable process that everyone follows is far more effective. Breaking it down into daily, weekly, and monthly tasks makes it easy for your team to get on board.

Here’s a straightforward plan any facility can use:

- Daily Sweep: Give the mats a quick sweep or brush-off at the end of each shift. This stops dirt and debris from getting ground into the surface, which is a fast track to premature wear and tear. Benefit: Extends mat life and maintains a clean appearance.

- Weekly Wash: Use a mild cleaning solution that’s right for the material and give the mats a good scrub with a deck brush. Stay away from harsh, caustic chemicals—they’ll eat away at rubber and vinyl over time. Benefit: Removes grime and maintains slip resistance.

- Monthly Inspection: This is the most important step. Do a thorough visual check of every single mat in your facility.

During your monthly inspection, you’re hunting for any signs of wear that could compromise safety. Look specifically for curled corners, deep cracks, or spots where the cushioning has gone completely flat and compressed.

Real-World Example: Picture a mat at a busy welding station. After a few months, one corner starts to curl up just a tiny bit. During the monthly inspection, a supervisor spots it and flags the mat for replacement. By catching it early, they prevent that small curl from becoming a persistent, dangerous trip hazard for every single person who walks by.

This is exactly why you can't afford to be reactive. Proactive inspection and replacement are non-negotiable. An old, worn-out mat is no longer a safety asset; it’s a liability waiting to cause an accident.

Got Questions About Industrial Matting? We've Got Answers.

When it comes to choosing the right anti-fatigue industrial mats, a few practical questions always come up. Getting these details right from the start can save you a lot of headaches down the line. Let's tackle some of the most common queries we hear from facility managers just like you.

How Thick Should My Mat Be?

This is a classic case where "thicker is better" isn't always true. While you might be tempted to go for the plushest option, the sweet spot for an industrial mat is typically between 3/8-inch and 5/8-inch.

Go too thick, and the mat can feel unstable underfoot, sometimes even becoming a trip hazard. Too thin, and it will just "bottom out" under a worker's weight, offering next to no real ergonomic support.

How to Choose:

- For a worker standing in one spot all day (e.g., at a press or inspection station), a thicker 5/8-inch mat provides fantastic cushioning.

- For areas with more foot traffic and movement (e.g., a packing line where people walk back and forth), a 3/8-inch mat is often the perfect balance of support and stability, with a lower profile to reduce trip risk.

When Should I Replace My Anti-Fatigue Mats?

The lifespan of an anti fatigue industrial mat really depends on the material it's made from, how heavily it's used, and how well you look after it. That said, safety comes first. You should replace any mat immediately if you spot these tell-tale signs of failure:

- Curled or Damaged Edges: This is a huge red flag. Curled edges are a serious trip hazard and mean the mat's structure is breaking down.

- Cracks or Tears: Any breach in the surface is a magnet for dirt and moisture, which quickly turns into a slip risk.

- Loss of Cushioning: If the mat feels flat, hard, and compressed when you stand on it, its ergonomic benefits are gone. It's no longer doing its job.

Actionable Takeaway: Implement a simple "tag and replace" policy. If an employee or supervisor spots any of these issues during a daily walk-through or monthly inspection, they should immediately tag the mat for removal and replacement. This proactive approach ensures a consistently safe environment.

It's no surprise that the global anti-fatigue mats market, valued at around USD 1.80 billion in 2024, keeps growing as more businesses realize replacing worn-out gear isn't an expense—it's an investment in safety and productivity. If you're interested in the data, you can explore the full research on anti-fatigue mat trends.

Ready to create a safer, more productive workplace? Explore the wide selection of durable and effective anti-fatigue matting solutions at Mats4U. Find the perfect fit for your facility today at https://www.mats4u.com.