Investing in the right industrial anti fatigue mat is one of the smartest moves you can make for safety and productivity in a tough work environment. This isn't just about comfort; it's a strategic decision that tackles the physical strain responsible for costly operational slowdowns and serious employee health problems.

Why Your Facility Needs the Right Matting

Standing for hours on hard concrete forces leg and back muscles to stay rigid and tense, which seriously restricts blood flow. This constant physical stress directly causes pain, exhaustion, and a whole range of musculoskeletal disorders (MSDs) that hurt your team and your bottom line.

A high-quality industrial anti fatigue mat is specifically engineered to fight back. Its cushioned-yet-supportive surface encourages tiny, continuous micro-movements in the leg and calf muscles. These subtle shifts get the blood flowing again, ease pressure on the spine, and make a massive difference in the fatigue that builds up over a long shift.

How to Achieve a Tangible Business Impact

The benefits of proper matting show up directly in your facility's performance metrics. Here’s how you can achieve similar results:

- Step 1: Identify Pain Points. Walk your facility and talk to your team. Pinpoint the workstations where employees report the most back and leg pain, or where you notice productivity drops late in the day.

- Step 2: Implement a Targeted Solution. Equip these specific high-strain areas with the correct type of heavy-duty industrial anti fatigue mat for the environment.

- Step 3: Track the Results. Monitor key metrics like absenteeism, reported MSD-related issues, and station-level output over the next 3-6 months.

Real-World Example: An automotive parts manufacturer was dealing with high absenteeism due to back and leg pain on its main assembly line. After following these steps and equipping the entire line with heavy-duty nitrile rubber mats, they tracked a 32% reduction in reported MSD-related issues within six months. This directly resulted in fewer sick days, more reliable staffing, and a clear improvement in the line's overall efficiency.

Actionable Takeaway: The right mat isn't an expense; it's a productivity tool. By reducing physical strain, you empower your crew to stay focused and energized, which directly translates to better quality work and fewer mistakes.

A Critical Component of Workplace Safety

The industrial sector purchases over 51.7% of the entire anti-fatigue mat market, which proves how essential these products are. From manufacturing plants to food processing facilities, businesses rely on these mats to combat the risks of long-term standing on unforgiving floors—a primary cause of joint pain and circulation issues.

Investing in proper matting is a proactive step toward improving employee wellness and cutting down on compensation claims. It's simply fundamental to creating a safer, more efficient, and more humane place to work.

Below is a quick overview of the key benefits you can expect when you implement a proper industrial matting solution.

Key Benefits of Industrial Anti Fatigue Mats at a Glance

This table summarizes the core advantages businesses gain from using the right anti-fatigue matting in their industrial settings.

| Benefit Category | Impact on Business | Example Application |

|---|---|---|

| Employee Health & Wellness | Reduces musculoskeletal disorders (MSDs), leg pain, and back strain. | Assembly lines where workers stand in one spot for extended periods. |

| Productivity & Efficiency | Increases focus and energy, leading to fewer errors and higher output. | A packing station where attention to detail is critical throughout the shift. |

| Safety & Compliance | Lowers the risk of slips, trips, and falls; helps meet health and safety standards. | Wet processing areas or machine shops where spills are common. |

| Financial & Operational | Decreases absenteeism, sick days, and workers' compensation claims. | Any industrial environment looking to improve operational consistency and reduce costs. |

Ultimately, a well-chosen industrial anti fatigue mat is an investment in your people and your process. For a closer look at the science behind how they work, check out our guide on what are anti-fatigue mats.

Matching Mat Materials to Your Workspace

Choosing the right industrial anti fatigue mat isn't like picking out a doormat. The material you select is the single most important factor that dictates whether your investment pays off in safety and longevity or just becomes another trip hazard that fails prematurely. A mat that’s a star performer in one environment could be a dangerous liability in another.

This is about problem-solving. You need to match the mat’s composition directly to the specific hazards and daily grind of your workspace. Let’s break down how to make the right call based on real-world industrial challenges.

Nitrile Rubber for Harsh Environments

For environments like an auto repair shop or a heavy manufacturing floor where oils, greases, and industrial fluids are common, 100% Nitrile Rubber is non-negotiable.

Unlike other materials, pure nitrile is inherently built to resist these substances. A lesser mat made from PVC or a cheap rubber blend will act like a sponge, absorbing oils and causing it to swell up, curl at the edges, and rapidly disintegrate. This doesn't just wreck the mat; it creates a serious trip hazard.

- Real-World Example: A CNC machine shop manager was constantly replacing mats that became slick and mushy within weeks due to cutting fluid exposure. By switching to a heavy-duty nitrile rubber mat, they achieved a surface that stays slip-resistant and structurally sound, protecting both their workers and their investment.

Polyurethane for Supreme Comfort in Dry Areas

For dry environments like an assembly line, a pharmaceutical packaging station, or a busy fulfillment center, the biggest enemy is the sheer fatigue from standing on hard concrete for 8 to 12-hour shifts. This is where Polyurethane mats shine.

Polyurethane delivers the gold standard in compression and rebound. It provides a plusher, more cushioned feel that offers exceptional ergonomic support, taking a significant load off feet, legs, and back. However, this premium comfort comes with a trade-off: it’s a no-go for areas with welding, sparks, or aggressive chemical contact.

- Real-World Example: A medical device packaging facility needed to boost comfort for technicians who stand for long periods inspecting small parts. They implemented polyurethane mats, which reduced reported leg fatigue and helped employees maintain the high level of focus needed for quality control throughout their entire shift.

The growing focus on employee well-being has pushed material science to the forefront. In fact, market projections show the anti-fatigue mat industry is expected to hit USD 3.37 billion by 2032. While rubber holds its ground for pure durability, polyurethane is quickly catching up in dry, comfort-focused roles. You can dig into more market trends on anti-fatigue mat materials at fortunebusinessinsights.com.

PVC and Vinyl Blends for General Purpose Use

For middle-ground areas like a quality control inspection station or a light-duty workshop with moderate foot traffic and no extreme hazards, a mat made from PVC (Vinyl) or a PVC/Nitrile blend is often a perfect fit.

These mats provide solid ergonomic benefits at a lower price point, making them a smart, cost-effective choice for less demanding spots. Many are designed with durable top surfaces that can handle light cart traffic or the occasional dropped tool without puncturing.

- Actionable Takeaway: When considering a PVC mat, always check the product's spec sheet for a chemical resistance chart. While it won't stand up to heavy oils, some advanced PVC blends are formulated to handle certain mild acids or cleaning agents, making them a viable option for specific lab or janitorial areas.

To help you sort through the options quickly, here is a practical comparison of these common materials.

Industrial Mat Material Comparison

This table is a practical cheat sheet to help you select the best anti-fatigue mat material based on your specific industrial needs and the environmental conditions your team faces every day.

| Material | Best For (Environment) | Key Strengths | Potential Weaknesses |

|---|---|---|---|

| Nitrile Rubber | Oily, greasy, or wet areas; welding zones; heavy manufacturing. | Excellent oil/grease resistance; high durability; heat resistant. | Firmer feel; higher initial cost. |

| Polyurethane | Dry assembly/packaging lines; pharmacies; fulfillment centers. | Superior comfort & cushioning; exceptional rebound and support. | Not for wet/oily areas; susceptible to sparks/welding slag. |

| PVC (Vinyl) | General purpose dry areas; light manufacturing; inspection stations. | Cost-effective; good durability; wide variety of top surfaces. | Degrades with oil/grease exposure; can crack in cold temperatures. |

In the end, the most critical step is an honest assessment of your worksite. Walk the floor. Identify every potential hazard—from chemical spills and hot sparks to heavy cart traffic—before you even think about looking at a product catalog. This methodical approach ensures the industrial anti fatigue mat you choose is a genuine solution that boosts safety and will actually stand the test of time.

Getting the Right Mat Size and Thickness

A common and surprisingly costly mistake is getting the mat dimensions wrong. When a mat is too small, workers are forced to step on and off the edge all day. This doesn't just cancel out the ergonomic benefits; it actually creates a brand-new trip hazard.

The goal is to provide a continuous, supportive surface for their entire work area. To get this right, you need to follow one simple but critical rule: measure the task, not just the feet. You must account for the full range of motion an employee uses to do their job.

How to Measure for Full Range of Motion

A worker rarely stands perfectly still. They pivot to grab tools, step sideways to use equipment, and constantly shift their weight.

If you just measure the 2x3 foot spot where their feet usually are, you'd miss the mark. You need to observe how they actually work.

- Step 1: Observe the Worker. Watch an employee perform their tasks for a full work cycle. Pay attention to how far they reach and step in every direction.

- Step 2: Mark the Work Envelope. Use temporary chalk or floor tape to mark the absolute outer limits of their movement.

- Step 3: Measure the Marked Area. Measure inside that taped-off area. These are the true dimensions you need for your industrial anti fatigue mat.

By measuring this entire "work envelope," you might discover that a standard 3x5 foot mat is far too small, and a 4x8 foot runner or a custom-cut solution is the only way to keep them safely on the mat at all times.

Real-World Example: A packaging station in a distribution center required workers to pivot left for boxes and step right for a labeling machine. By marking out this full range of motion, the manager realized they needed a 4x6 foot mat, not the 3x5 they had assumed. This change eliminated the constant, awkward shuffle on and off the mat edge, reducing trip risks.

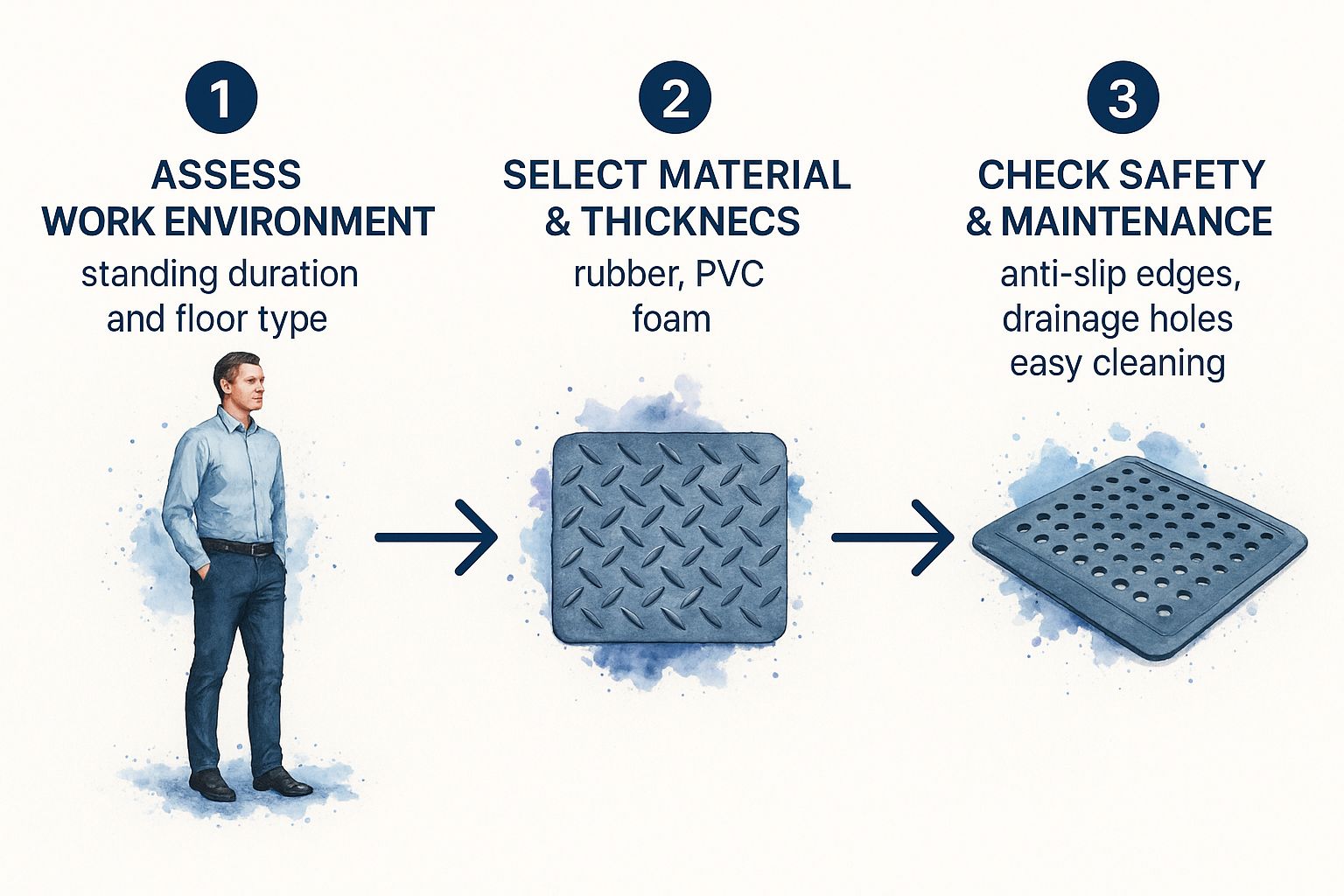

This quick infographic nails the core thought process for choosing the right mat.

It breaks it down into three clear stages: figure out what your specific environment demands, pick the material and thickness based on that, and finally, make sure it has the right safety and maintenance features.

How to Match Mat Thickness to Workplace Demands

Once you've nailed down the size, thickness is your next big decision. Go too thin, and the mat will "bottom out," offering little support. Go too thick, and it can feel unstable. The right thickness comes down to two things: shift length and worker weight.

- For Standard 8-Hour Shifts: A 5/8-inch thick mat is the industry standard, providing a great balance of cushion and support for most people.

- For Extended or Multi-Shift Operations: For 10-12 hour shifts or 24/7 operations, upgrade to a 7/8-inch or 1-inch mat. This will deliver the extra compression and resilience required to fight fatigue over longer stretches.

A 5/8-inch mat may be inadequate for a 250-pound employee. For heavier workers or in areas with staff of all sizes, playing it safe with a thicker 7/8-inch mat is a smart move to ensure everyone gets the support they need. The lifespan of the mat is also part of the equation; you can learn more about how long do anti-fatigue mats last in our other guide.

At the end of the day, getting the size and thickness right is non-negotiable. It's the foundation that ensures your matting program actually delivers on its promise of a safer, more comfortable, and more productive workplace.

Don't Forget These Critical Safety Features

The comfort of an industrial anti fatigue mat is meaningless if the mat itself creates a new hazard. In any fast-paced workplace, safety must be the top priority. Some features aren't just "nice to have"—they're non-negotiable for protecting your crew.

A mat's ergonomic benefits are completely wiped out if it becomes a tripping hazard. According to the National Safety Council, slips, trips, and falls accounted for 20% of all employee days away from work in 2023. This statistic alone should make you scrutinize a mat's safety design before you buy.

Eliminate Trips with Beveled Edges

The single most critical safety feature is beveled, or sloped, edges. A mat with sharp, 90-degree edges is an accident waiting to happen. A squared-off edge is like a tiny curb that can easily catch a foot or a cartwheel.

A low-profile beveled edge, especially one marked with high-visibility yellow, allows feet and carts to glide on and off smoothly. This simple design feature transforms the mat from a liability into a seamless part of the floor.

- Real-World Example: A logistics facility manager was seeing many near-misses around workstations where carts were used. After swapping their old, curled mats for new ones with bright yellow beveled edges, cart traffic flowed perfectly, and trip incidents dropped to zero. The mats now act as a visual guide for safe pathways.

Anchor Your Mat with Non-Slip Backing

A mat that slides is just as dangerous as one that trips people. The backing is what gives a mat its "grip," ensuring it stays put. Whether your floor is polished concrete or sealed epoxy, a high-traction, non-slip backing is essential to anchor the mat firmly, especially in areas where workers pivot or make quick lateral movements.

For a deeper look at preventing slips, our guide on industrial non-slip mats offers more detailed advice for really challenging floors.

Address Specialized Environmental Hazards

Your specific environment might have other hazards that demand specialized mat features. Ignoring these can lead to damaged equipment or serious accidents.

Here is how to solve common environmental challenges:

- For Wet Areas: If you work in food processing, a commercial kitchen, or a machine shop where liquids are present, you need a mat with drainage holes. These let water, oil, and other fluids pass through, keeping the top surface drier and safer.

- For Electronics Work: In electronics assembly or repair, a standard mat can build up static. An unexpected discharge can fry sensitive components. Electro-static dissipative (ESD) mats are designed to safely drain static away, protecting both the worker and the product.

- For Sparks or Chemicals: If your work involves welding or harsh chemicals, you must use a mat explicitly rated for it. A spark-resistant mat won't ignite from hot slag, and a chemically resistant one won't break down and become a gooey mess.

Making these features part of your buying checklist is how you ensure your new mats are an active part of a safer, more secure workplace.

Get the Most Out of Your Mat: Installation and Maintenance Tips

You’ve invested in a quality industrial anti fatigue mat. Now the real work begins: making sure it lasts and continues to deliver the safety and comfort you paid for. Proper installation and routine care will separate a mat that lasts a year from one that performs flawlessly for many years to come.

How to Install Your Mat for a Good Start

A great mat can get off to a terrible start if you rush the installation. The most common mistake is unrolling a new mat and immediately putting it to use, which often leads to curled edges that create a stubborn trip hazard.

Here's a simple, patient process to follow:

- Acclimate the Mat: Let the new, rolled-up mat sit in the room where it will be used for at least 24 hours. This allows the material to adjust to the building's temperature, making it more pliable.

- Unroll and Settle: Unroll the mat and let it lay flat. If an edge is still curling up, lay a flat, weighted object—like a clean piece of plywood—on the problem area overnight. This ensures a safe, flush transition from mat to floor from day one.

A Simple Cleaning Routine That Actually Works

Just like any other piece of equipment, your anti-fatigue mats need a basic cleaning schedule to stay safe and effective. A dirty mat isn’t just an eyesore; the grit and grime can act like sandpaper, breaking down the surface and ruining its slip resistance.

Here’s a practical, no-fuss cleaning schedule:

- Daily Sweep: At the end of every shift, sweep or brush off loose dirt, metal shavings, and other debris. This takes less than a minute but prevents abrasive bits from being ground into the mat surface.

- Weekly Mop: Once a week, use a deck brush or mop with a pH-neutral cleaner. Harsh chemicals will destroy the mat’s material over time.

- Immediate Spill Cleanup: When something spills, clean it up right away according to your facility’s safety protocols to avoid permanently damaging the mat.

This proactive stance on worker well-being is why the industrial matting market, valued at USD 1.80 billion in 2024, is expected to hit USD 3.09 billion by 2034. This growth is a direct result of stricter labor welfare policies pushing companies to prioritize employee health. For a deeper dive, you can read the full research about the anti-fatigue mats market.

Two Mistakes That Will Ruin Your Mats

Knowing what not to do is just as important as having a cleaning schedule.

-

Using a Harsh Degreaser on the Wrong Mat: A heavy-duty degreaser is essential in a greasy machine shop, but using it on a standard PVC or polyurethane mat will make the material brittle, causing it to crack and fall apart. Always match your cleaning chemicals to your mat’s material specifications.

-

Pressure Washing a Mat Not Designed for It: A pressure washer can strip the textured top surface right off a mat, destroying its slip resistance. It can also force water deep into the mat’s core, leading to internal damage. Unless the manufacturer explicitly states the mat is safe for pressure washing, stick to a mop and brush.

Common Questions About Industrial Mats

Even with a good plan, practical questions always come up when choosing and using an industrial anti fatigue mat. Getting straight answers to these common sticking points can be the difference between a confident investment and a costly mistake.

How Often Should We Replace Our Mats?

There's no magic expiration date; a mat's lifespan depends on use, environment, and quality. However, you must be proactive.

Actionable Step: Schedule a visual inspection of every mat every 6 to 12 months. During this walkthrough, look for these specific signs of failure:

- Curling or Rippling Edges: This is an immediate trip hazard.

- Cracks, Splits, or Tears: This compromises the mat's integrity and traps dirt.

- Visible Compression: If the mat looks "bottomed out" and has lost its bounce, its ergonomic benefits are gone.

- Loss of Traction: If the surface feels slick, its slip-resistance has worn away.

In a tough, 24/7 manufacturing plant, a mat might last 1-2 years. In a lighter-use area, it could last 3-5 years. Replace it the moment it shows signs of failure.

Can We Connect Multiple Mats to Cover a Large Area?

Absolutely. For large or awkwardly shaped areas, modular or interlocking tiles are the smartest approach. This is the perfect way to outfit long assembly lines or U-shaped work cells where a standard mat won't fit.

When choosing a modular system, look for a secure, seamless lock to prevent creating new trip hazards at the seams.

- Actionable Takeaway: Before committing to a full system, ask for a sample tile. Test how the pieces snap together. Is the connection tight? Is the seam flush? A quick hands-on check will tell you everything you need to know about its safety and long-term performance.

Does the Color of an Industrial Anti Fatigue Mat Matter?

Yes. While color doesn't change cushioning, it plays an important role in workplace safety and organization. Use color as a strategic tool:

- Bright Yellow or Orange Borders: These are excellent for marking designated walkways or highlighting hazard zones around machinery. The high-contrast border instinctively draws the eye, helping to prevent trips.

- Darker Colors (Black, Gray): These workhorses are great for high-traffic zones because they do a much better job of hiding dirt and scuffs, keeping the area looking cleaner.

So while a solid black mat and a yellow-bordered one might offer the same comfort, the bordered version adds a critical layer of visual safety communication. Understanding the full range of anti-fatigue mat benefits helps you see beyond just cushioning.

Are These Mats Okay for Carts or Forklifts?

This is a hard no for most standard anti-fatigue mats. They are not built to handle the focused weight of heavy rolling loads and will be quickly destroyed.

However, for these exact situations, you can find specialized mats specifically marketed as "crush-resistant" or "forklift-safe." These are made from ultra-high-density rubber or tough vinyl compounds that can take the punishment of wheeled traffic while still providing ergonomic relief. For dedicated forklift routes, though, matting is generally not the answer; it's better to keep matting focused on the stationary workstations where your team stands.

Ready to find the perfect matting solution that combines safety, durability, and comfort for your team? The experts at Mats4U have over 50 years of experience helping facilities like yours enhance productivity and protect their most valuable assets. Explore our wide range of industrial anti-fatigue and commercial mats today.